Biomass as a Fuel Source

| Conclusions |

Introduction

This section gives a background of the different forms that biomass fuels

can take.

Organic residues and wastes will be explained briefly. Forestry production

and residues will be explained in the context of the UK, focusing on the

potential supply and forms that wood fuel is sold in. A brief description

of the types of agricultural residues and wastes is given along with amount

of production and current uses. An overview of energy crops along with

advantages and disadvantages is also provided.

In the energy context, the term biomass is used to describe recently living

matter that is used to produce energy. Biomass is produced by organic

residues and wastes or by specifically growing crops for energy production.

It has been a principle source of energy for many centuries and still

is in many developing countries. Using biomass as a fuel to displace fossil

fuels can reduce carbon emissions and can offer fuel security without

the need to rely on imported fuel.

Biomass is considered to be carbon neutral because the quantity of CO2 released during combustion is the same as that absorbed by the plant during photosynthesis. This differs from fossil fuels in that, although both originating from organic matter, the carbon in fossil fuels has been locked away for millions of years, and when released during combustion, disrupts carbon dioxide levels in the atmosphere.

In reality, biomass is not completely carbon neutral as there are carbon emissions associated with processing the fuel and other possible emissions of green house gases from, for example, fertiliser use. There may also be carbon costs with transportation of biomass and the technologies used. Biomass is also considered environmentally sustainable since in many cases it is derived from the waste products of other industries such as agriculture and forestry management.

Biomass has several potential advantages when compared to other renewable energy resources. One of the main advantages is it can be used for heat, power and combined heat and power (CHP). As well as being able to produce continuous energy, and therefore not have intermittency problems, like those associated with wind and solar etc, it is also controllable so can be adjusted to meet demand. Biomass can be applied to a wide range of scales from 50kW domestic systems, medium 500kW plant to mega watt scale power stations.

Some biomass sources require fuel processing activities for example harvesting,

drying and chipping in the case of woodchips. Therefore when compared

to other renewable energy sources there is greater potential for creating

jobs and stimulating rural development.

There are two kinds of biomass resources, organic residues/wastes and

energy crops. These will now be explained in more detail.

Organic Residues and Wastes

Municipal Solid Wastes (MSW)

Municipal Solid Waste refers to a combination of domestic, light industrial and demolition solid wastes, generated within a community. At present there are three main ways of treating MSW; disposal in landfills, combustion and disposal in anaerobic digesters.

Incineration of waste can be problematic as the composition of the waste

is varied and pollutants such as dioxins, heavy metals, acidic gases,

nitrogen oxides and particulates. These can have an effect on health and

impact upon the environment when emitted during incineration. At present

public opinion surrounding incineration of MSW in Energy from Waste plants

is negative due to the fears regarding these pollutants. However, waste

incineration is heavily regulated at many levels by SEPA in Scotland,

and The Environment Agency in England and Wales. The EU Waste Incineration

Directive introduced tight emission standards for waste incinerators,

thus reducing the amount of pollutants entering the atmosphere, making

it more plausible that there may be more energy from waste plants in the

near future. Because of these fears and heavy regulations, it would be

advised that biomass from MSW is only economically viable for large commercial

power plants.

Commercial and Industrial Waste:

Commercial and Industrial residues, wastes or co-products, of organic

origin, can be potentially used or converted to biomass fuel. These residues,

wastes and co-products arise from commercial and industrial process and

manufacturing operations. Around 36 mega tonnes of specialized wastes

is generated in the UK each year and about one third of this is combustible.

For example, the furniture industry has been estimated to burn 35,000

tonnes of off cuts and sawdust per year, which is about one third of its

production.

The wastes produced by commerce and industry can be split into two categories, woody materials and non-woody materials.

- Woody Wastes: Woody wastes are essentially the same as wood fuel, for instance sawdust. However, they may incorporate contaminants from intended treatments, finishes or manufacturing processes or accidental chemical spillages or other contaminants. It can be used in the same manner as wood fuel in that it can be burned for heating, power or CHP or can be gasified or pyrolysed. The technologies for making use of woody wastes is the same as for wood fuel, however, there are regulatory and environmental constraints for these conversion to fuel techniques because of the contaminants in the material.

- Non Woody Wastes: A number of industries generate

non wood wastes that have potential as biomass fuel. Included in non

wood wastes are materials such as paper pulp/wastes, textiles and sewage

sludge.

Paper pulp/wastes and textile waste can be combusted gasified or pyrolysed. However, inks, dyes and surface treatments may contain heavy metals or other contaminants, so when combusting, bottom ash and fly ash must be disposed of appropriately.

Sewage sludge results from the separation of solids from liquids during waste water treatment. Sewage sludge has a high moisture content so would be best suited for anaerobic digestion as drying, for use in combustion, gasification or pyrolysis, although possible, is very costly.

Forestry Production / Residues

In the UK forestry is primarily directed towards the production of timber and paper pulp. This has not always been the case as historically wood cuttings fuelled domestic and industrial stoves, and provided the raw material for charcoal.

Forestry is facing changes because the demand for paper pulp is decreasing as recycling is increasing and more correspondence is conducted through the internet while the demand for construction timber is also on the decline. As a result of this and the fact that large amounts of UK forestry, planted in the 1960’s and 1970’s, will be reaching maturity soon, means that there will be an increased amount of forestry products available to use as wood fuel.

During the literature review conflicting views of supply and demand were found for wood production. One explanation for this could be because wood as a biomass fuel source on a large scale is still in its infancy. Because of this there have been many reports commissioned to analyse the wood fuel potential in the UK.

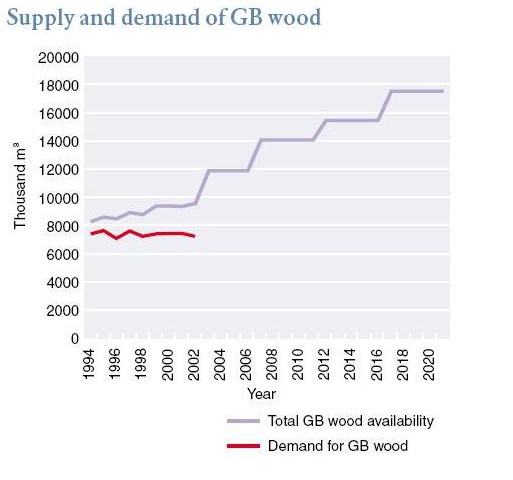

Graph 1, taken from the Royal Commission on Environmental Pollution, shows that supply is predicted to increase until it reaches a peak, of just under 18 million m3, in the year 2018. The demand for wood has not been predicted though it may increase over this period due to an increase in building houses, which is foreseen in Government strategies for housing and planning2.

Graph 1: Supply and demand of GB Wood2

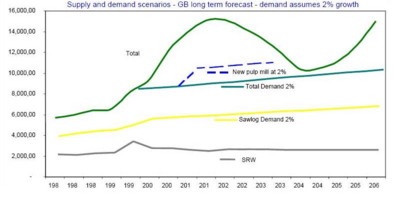

Graph 2 is taken from the Scottish Executive, which also shows that supply is expected to exceed demand within 15 years.

Graph 2: GB long term forecast-Supply and Demand Scenarios3

The above two sources are very positive about wood production in the UK. However, the ‘Forecast Wood Fibre- Part 14’ report has a different forecast of wood production with supply being able to meet projected demand. It states “forecast demand for coniferous roundwood and sawmill co-products from planned developments by the forest and wood energy industries will exceed the potential availability of these two fibre sources from 2007 to 2016”.

Forestry residues arise from forestry operations such as thinning plantations and trimming felled trees to prevent forest fires and accelerate growth. These residues and wastes offer a large potential for an energy supply.

Although differing facts and figures about supply and demand of wood

production was found during the literature review it should not deter

people from considering wood as a fuel source. These reports all have

slightly differing figures but most reports agree that supply, especially

in Scotland, will be able to support further demand growth especially

at this early stage in the biomass industry. This coupled with the Governments

commitment to renewable energy makes wood a promising biomass fuel.

Currently the main demand for wood, from forestry materials, comes from

sawmills. Sawmill products can be used as a biomass fuel either as sawdust

to be compressed into pellets or off-cuts suitable for chipping. The main

competition is from chipboard manufacturers, although they too produce

by-products that can be used for energy production. Thus sawmills and

chipboard producers are ideal candidates for producing pellets onsite.

In addition to this they can also use their own biomass to produce combined

heat and power that can then be used, amongst other applications, to power

the pelletisation process. One example of a company that does this is

Balcas Ltd in Northern Ireland. They own four sawmills, two pellet factories

and an MDF mouldings plant. Balcas Ltd uses surplus sawdust and woodchip

from the sawmill to produce CHP, which is used to dry further wood, to

produce wood pellets, as well as provide CHP for the entire facility.

This scheme therefore disposes of the mill products in a safe and convenient

way, bringing more income to the company and cutting energy and fossil

fuel consumption.

With an increase in pellet production, some European countries, especially Austria have seen a dramatic increase in small scale domestic wood fuelled heaters.

In Britain, it is estimated that sawmill co-products total around 859 K odt/y, 20% of which is sawdust2. Although 98%2 already has a market, it is estimated by the Forestry Commission that around half of the sawdust could be made available for fuel without serious disruption to existing industries. At the moment, a significant increase in pellet production in the short term will have to come from other sources of wood, such as forest materials or short rotation coppice. In the future, increases in availability of sawdust for pelletisation will come from either an increase in sawmill activity or a decrease in other markets for saw mill co-products. This trend can be explained due to the fact that wood pellets have a much higher economic value to the sawmill than producing chipboard.

Wood: Wood is the most common form of biomass and has

been burned for thousands of years for heating and cooking. The term ‘wood’

includes products such as wood, sawdust and bark that has not been chemically

treated or finished. This ‘wood’ can be obtained from a number

of sources such as forestry, saw mills and timber merchants.

When buying wood for fuel, the physical forms it can be bought in are

logs, sawdust, woodchips, wood pellets and briquettes. The lower the moisture

content the better the calorific value of the wood product as a fuel.

| Logs: Logs can be bought directly from a supplier once they have been left to dry for a period of time to reduce the moisture content and then burnt directly in a boiler or domestic stove. These can not be loaded automatically however and are therefore not suitable for large buildings. |  |

Sawdust: A typical by product of wood processing or manufacture is sawdust and this can have either a high moisture content or a low moisture content depending on its source. An example of sawdust with high moisture content would be from cutting wood and an example of sawdust with low moisture content would be from furniture manufacturing. Although sawdust has a low energy content, it has a large surface

area to volume ratio so can be suitable for blowing into some combustion

or gasification systems. Dry sawdust is particularly suitable for

processing into pellets. |

|

| Wood Chips: Wood chips, when compared

to logs, offer a much more uniform fuel that can flow and be automatically

fed, using an auger feed or a conveyor belt, into a boiler, gasifier

or other combustion system at a steady rate. Woodchips are convenient

to transport and they have a large surface area to volume ratio, which

means that they can be burnt efficiently.

Wood chip systems generally have an output of 20kW upwards, anything less is not cost effective, making them unsuitable for most domestic scale applications. Wood chips are typically 20mm-50mm long and there are quality control standards that they must meet when used for energy applications (CEN/TC355)1. The main criteria are raw material, size of chip and moisture content1 |

|

Larger biomass systems can take larger chip sizes, known as hog fuel and measuring 100mm in length but long thin wood chips, known as slivers, should be avoided as they can cause blockages and bridging in a chip feed system.

The characteristics of wood chips depend on the original source, from which they are made, and on the chipper. Forest chips include; log chips made from de-limbed stem wood; whole tree chips made from all the above ground biomass of a tree; logging residue chips made from branches, brash etc. and stump chips made from stumps. Wood residue chips are made from untreated wood residues, recycled wood and cut offs. Sawing residues produce sawing residue chips and other chips are made from short rotation coppice or short rotation forestry5.

Role of Storage: When considering wood chips for a biomass system it is important to consider the storage arrangements as storage facilities for wood chips can be very large. There can also be potential problems with composting in large piles of chips, this can lead to loss of biomass and spontaneous ignition from the rising temperatures, and it is therefore advised not to have piles of woodchips higher than 10 meters so as to prevent excessive build up of heat. However, if the heat from composting is managed properly it can help reduce the moisture content of the chips. If an automatic feed is to be considered the positioning of the boiler and storage unit must be carefully thought out.

Wood Pellets and Briquettes: Wood pellets and briquettes

need to be made from a fine dry feedstock so tend to be made from sawdust

or other by products of the wood processing industry. They can be made

from freshly felled timber but the grinding and drying processes involved

are less energy efficient and could significantly add to costs.

Producing wood pellets is more energy intensive than that of other wood

fuel and the process generally consists of obtaining a supply of dry,

uniform sawdust and extruding them through a die. The pellets are then

cut to length and packaged for delivery.

The production of wood pellets is more energy intensive than that of other wood fuel production, with 10% of the pellets own energy content being used in production when using wet, fresh sawdust and 2% of the pellets own energy content when using dry sawdust1. However wood pellets do have a higher calorific value than woodchips meaning than more energy can be obtained per delivery, reducing transport energy impacts. Currently wood pellets are produced by large scale industrial pellet manufacturers with links to large saw mills and/or pellet clients thereby making the production costs more economically viable.

Wood pellets, at present, are more popular with domestic users because they are less bulky to store, easier to handle and more suited to automatic handling systems because they are of a consistent size, when compared to other wood fuel sources. They also have a low moisture content 8%-10%, and a consistent density and heat content1. These characteristics would benefit larger sized boilers as well, however, sourcing large amounts of pellets and the cost of purchasing pellets may negate the environmental and economic benefits of owning a biomass boiler. Also, larger biomass boilers tend to be able to take wood chips as they do not have as delicate a feed system as the smaller domestic boilers.

Agricultural Residues/ Waste

Agricultural residues and wastes are defined as the by-products of the

agricultural system and can be split into two types, dry and wet.

Dry residues consist of parts of arable crops that are

not used for the primary production of food or fibre. Included in dry

residues are straw, poultry litter and corn stover.

Below is a table describing types of agricultural residues/ wastes, their production in the UK and their uses.

| Dry Residue | Description | Production in UK | Current Uses | Energy Uses |

| Straw | By-product (dry stalk of) a cereal plant, such as wheat and barley. | Excess of 10 Million tonnes/ year | • Animal bedding and feed. • Returned to the soil. |

• Combustion • Gasification |

| Poultry Litter | Wood shavings or straw used in deep litter broiler houses, including droppings | 15 million tonnes of poultry droppings in addition to the straw or wood shavings | • Incineration • Deep ploughing • Buried • Fertiliser (not ideal in certain cases such as cattle, hay, silage) |

• Combustion |

| Corn Stover | Stalk and leaf residues from harvesting maize for grain | 100,000 ha grown for forage and used for silage. 2,500 ha for grain. | • Grazed as forage • Collected as fodder |

• Combustion • Gasification |

Table 1: Agricultural residues/ wastes and their uses5

Wet residues typically consist of animal slurry and farmyard manure and grass silage. They are primarily used as fertilisers. They have a high moisture content and are more suited to anaerobic digestion for the production of biogas. This is best done close to the source as the energy and financial costs of transporting wet residues is very high. Below is a table showing the amount of animals in the UK and their corresponding slurry production per year.

| Animal Type | Amount of animals in UK (Million) | Slurry Production per year (Million Tonnes) |

| Dairy Cattle | 2 |

20 |

| Beef Cattle | 1.8 |

5 |

| Pigs | 4.9 |

Unknown |

| Sheep | 20 |

Unknown |

Table 2: Amount of animals and corresponding slurry production5

Food Waste: Residues and wastes occur at all points in the food supply chain. A majority of food waste has a high moisture content and can be used in anaerobic digestion. Wastes that have high starch or sugar levels are potentially suitable for fermentation into bioethanol and it is worth considering oil wastes for the production of biodiesel.

Energy Crops

Energy crops, in the widest sense, encompass plants/crops that are purposefully

planted to be used as fuel or converted to biofuel. The primary objective,

when selecting energy crops, is to obtain the highest possible amount

of energy given the climatic conditions.

Energy crops are attracting increasing attention as they are seen as an

indigenous alternative to fossil fuels that can reduce CO2

emissions and the need to import oil and gas.

Methods for growing energy crops include short rotation forestry (SRF)

and short rotation coppicing (SRC).

Short rotation forestry involves planting trees close together and felling

them when they have reached a diameter of 10-20cm at breast height. This

can take 8-20 years depending on tree species. The effect this has on

a plantation is to keep the high productivity of a young plantation whilst

increasing the wood to bark ratio. Of the species trialled, ash and alder

have proved to be the most suitable species for the UK. Ash needs good

soil that is not acidic, to grow in and alder is more suited to poorer

wetter soils. In the short term SRF is not seen as a major source of biomass

fuel.

Short rotation coppicing generally involves cutting back a crop species

in the first year to encourage rapid, thick growth in the following three

years, after which it is ready for harvesting. In the UK, Willow and Poplar

are the principal species used in SRC for energy use. The table below

lists some forms of potential crop species and the advantages and disadvantages

associated with their production.

| Species | Advantages | Disadvantages |

| Willow | • Roots are a mat like mass immediately below the surface

of the soil, helping to retain loose topsoil. • Has a leafy canopy so during heavy rainfall saturation of soil is prevented, reducing soil erosion and loss of nutrients. • Few pesticides are needed as levels of pest or pathogen damage can be higher for combustion than that of food production. • Development of a step-planter, that can cut stems into 15cm sections and deposit them in the soil, is being developed in Sweden. • Can absorb heavy metals in the soil, from sewage used as fertiliser, and concentrate them in the wood. |

• Rabbits are pests and rabbit proof fencing can be costly. • UK transportation and infrastructure is not able to match rate of willow chip production, so transport and storage of chips can be costly. • Currently farmers consider willow as a marginal crop and subsidies are used to plant on set aside land, which can sometimes be of low quality, resulting in low yields. • A substantial amount of water is needed so a good watering system is required or planting in wetter regions. However, in the UK dryer areas have produced successful crops. |

| Poplar | • Willow harvesting methods, already established could be

relevant for poplar. • Yields of poplar have outperformed willow by up to 66% in some cases. |

• Compared to Willow, planning is difficult because good apical

buds are needed for effective planting and growth. • Planting machinery has not yet been developed, presently cabbage planters are being used and success is limited. |

| Miscanthus | • Grown using conventional agricultural methods and harvested

yearly. • Harvested and stored using existing farming equipment and methods. • Already widely grown as an ornamental plant. • Less capital costs because of this. • Economical in its use of nutrients • Good internal recycling system. |

• Deep root structure makes it difficult to rehabilitate and

use the land for other crops. • Experience and information is limited as fewer sites have been planted for energy purposes. |

Table 3: Biomass fuel crops, Advantages and Disadvantages2

Another advantage of planting energy crops, in particular short rotation coppice is the cover provided attracts small mammals, invertebrates and insects, which in turn attract small birds2. Larger mammals are also attracted to this type of plantation. These combined can offer biodiversity to the land. However, care must be taken in the planning stages so that biodiversity is enhanced and not reduced, as could be the case if wetlands are replaced. Despite the disadvantages, short rotation coppice provides a promising solution to bio fuel diversity and it should be encouraged as much as possible.

Conclusions

There are many potential biomass sources available, with varying advantages and disadvantages. Although municipal solid waste is heavily regulated and faces opposition from the public it does provide a feasible solution to waste production and can prove economically viable for large commercial power plants. Commercial and industrial wastes can provide a large amount of biomass material and is promising for use on the site where it is produced. Forestry production and residues are seen as a very promising biomass fuel source in the UK, particularly Scotland and the conversion process into fuel is comparatively simple, as are the regulations surrounding it. Agricultural residues and wastes have a large potential for use as a biomass fuel. However, some residues, such as slurry, are particularly wet so are more suited to anaerobic digestion onsite, and therefore not widely available. Energy crops are in their infancy at the moment but hopefully with time they will become more popular and the technology and information can be improved for greater yields, thus providing a reliable biomass fuel source for the future.

Footnotes

- Wood Energy

- Royal Commission on Environmental Pollution, 2004.

- Scottish Executive, 2005.

- Forecast Wood Fibre Availability & Demand in Scotland & Northern England to 2016, 2006.

- Biomass Energy Centre

Bibliography

Scottish Forestry Industries Cluster

Forecast Wood Fibre Availability & Demand in Scotland & Northern England to 2016. 2006. Part 1 Report- Availability and Demand for Coniferous Roundwood and Sawmill Co-products. Prepared for The Wood Fibre Processing and Supply Industry. John Clegg Consulting Ltd with Cawdor Forestry Ltd.

Royal Commission on Environmental Pollution, 2004. Biomass as a Renewable Energy Source.

Scottish Executive, Forum for Renewable Energy Development Scotland, 2005. Promoting and Accelerating the Market Penetration of Biomass Technology in Scotland. Crown Copyright.