Balmenach Distillery

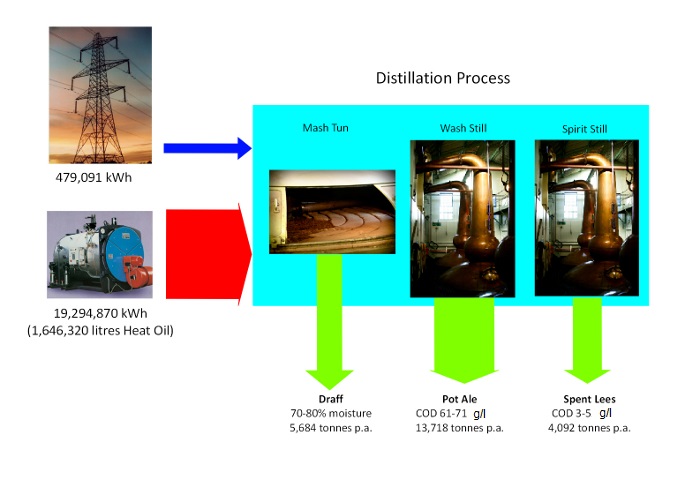

Balmenach distillery is a traditional malt whisky distillery 1 mile from Cromdale in Speyside producing around 2.3 million litres of alcohol per annum. Balmenach’s energy requirements and co-product production data for 2010 are illustrated below:

Key Points:

- The distillery is not connected to the mains gas grid, and process steam is currently raised in a 6,400kW rated oil fired boiler.

- Steam demand for the boiler is dependent on the batch distillation process.

- The distillery has 3 wash stills and 3 spirit stills which in 2010 were run on a batch basis in either 6 day or 7 day shifts, with some expectation to move to 7 day shifts only in the future.

- Cooling of the distillation products is by traditional ‘worm tub’ condensers with cooling water leaving at around 50°C, limiting heat recovery potential.

- Electrical distribution is at 132kV.

- The distillery is situated inland with a burn nearby and around ten houses in the immediate vicinity of the distillery.

- Both solid and liquid co-products are currently converted to animal feed at the Rothes Dark Grains Plant.

- Due to the demolition of redundant maltings there is significant space available on-site for development.

Existing Energy Supply:

- Steam for stills is supplied by single 6,400kW Cochran oil fired boiler installed 2 years ago; a biomass boiler was preferred but not available at the time of purchase. Steam leaves boiler at 7 bar g and is throttled to 3 bar g before stills. Annual oil demand for 2010 was 1,646,320 litres, costing £782,002 at an average cost of 47.5p/l. Feed pre-heat is via heat recovery from the distillation products.

- Mains electricity supplies lighting, space heating, electric pumps and yeast refrigerators. Annual demand for 2010 was 479,091kWh at an average cost of 10.5p/kWh.

It is considered that there may be potential to produce useful amounts of heat, power, or both from the co-products of the distillery and the options available will be investigated in this study. Data and assumptions used are detailed in Appendix D.