Case Study #2

Glycerine Applications

Finally, considering all alternatives mentioned previously, the best solution

for the farm’s needs would be the glycerine burner.

This is a picture received from one of the manufactures showing the main parts

of the equipment.

|

|

All glycerine burners are fed with a mixture of biodiesel or vegetable oil to the glycerine. In this case, a mixing unit is also needed.

Feasibility analysis and conclusion

Based on the amount of glycerine produced per month with the biodiesel production,

it is estimated that around 46,000kWh/month can be generated in the farm.

The burner can be easily integrated to the current heating system to provide

hot water and heating. The burner can substitute the existing boiler or work

in parallel, giving more stability and flexibility to the facilities in the

farm.

Considering that glycerine will be burned with 12% of biodiesel, which has

a cost of opportunity of £0.73/l, the following results are obtained:

Price of biodiesel |

£ 0.73 |

% of biodiesel in the mixture |

12% |

Net savings per month |

£ 353.96 |

Interest rate |

4% |

Pay-back |

6.33 (6 years and 3 months) |

Break-even |

7.44 (7 years and 5 months) |

NPV |

£7,552.00 |

These results show that the burner can not only solve the problem of storage

of glycerine in the farm but also be an investment with some return.

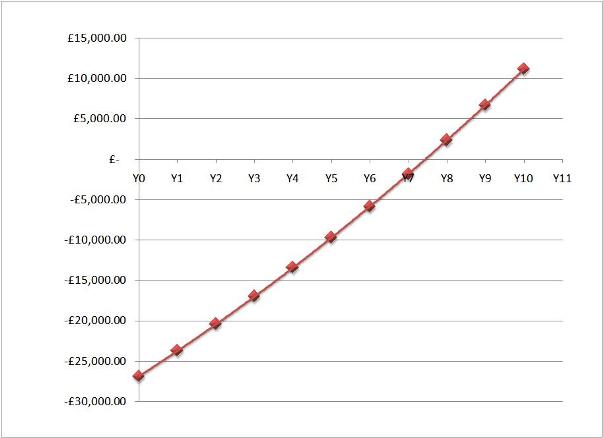

The cost analysis shows that the installation will have a pay-back in 6.3

years. The break-even is in 7.4 years and the Net Present Value for 10 years

is £7,500.00

It is important to notice that percentage and cost of biodiesel to be burned with the glycerine have great influence in the model. Changes in these parameters can affect the result and the conclusion of the feasibility study.

For improvement of these results, the following refinements can be performed:

-

Request of proposal for glycerine burner manufacturers and explore more details of the equipment.

-

Detailed specification of the integration of the burner in the heating system.

-

Detailed cost estimate, including costs of fitment and annual maintenance.