Case Study # 1

Heat Recovery System

Recommendations

Comparison

The following table compares both heat exchangers mentioned in the previous results page:

Manufacturer/origin |

Ygnis (France) |

Bowman (UK) |

Characteristics |

4 tube passes, counter-flow |

Shell and tube, counter-flow |

Maximum admissible temperature |

280 ºC |

700 ºC |

Main application |

Exhaust gas from Boilers |

Exhaust gas from gas/diesel engines |

Energy recovered |

255 kWh/day |

300 kWh/day |

Estimated cost |

£ 1,200.00 |

£ 4,000.00 |

As it can be seen on the previous table, the Totaleco will not be able to

recover as much heat as the Bowman heat exchanger will. However, considering

that the Bowman heat exchanger is three times as expensive as Totaleco, and

that the energy recovered is just 45 kWh/day lower, Totaleco is going to be

considered in this study. For a small installation as the Dowhill farm, this

seems to be the best alternative.

Design of the closed loop integrated into the boiler room

Once the selection of the heat exchanger is done, its integration to the

existing installation has to be considered. In order to do so properly, a

brief estimation of the needs of the farm has been assessed. Based on the

capacity of the boiler in site, it was estimated that an average of 480 kWh/day

is needed for space heating and to produce hot water for the facilities. Considering

this value, the existing boiler cannot be substituted by the heat exchanger,

but its use can be reduced considering it as a back-up. Many configurations

are available to integrate the heat exchanger to the heating system; however,

the ones chosen for the project are those that combine it as an economiser

of the boiler (inlet temperature: 60°C/ outlet: 80°C).

The loop is integrated to the inlet of the boiler. In this way, the heating

water will be pre-heated in this loop before going to the boiler. Then, if

the temperature is high enough, the boiler does not need to be activated.

Consequently, the overall consumption of gas for space heating and hot water

production will decrease.

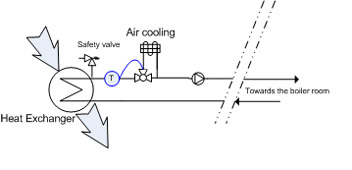

Loop including regulation integrated as an economiser

The heat exchanger is directly integrated to the heating system. A pump is provided circulate the water. An air cooling heat exchanger is foreseen to release excess heat in the system if the water temperature is higher than 80°C. The three way control valve will control this equipment.

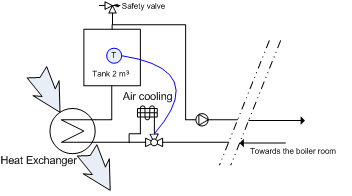

Loop including regulation and storage integrated as an economiser

Considering that the heat exchanger cannot be bypassed and consequently sometimes

it will recover more heat than needed, storage can be integrated. It has been

sized to store the energy provided by the maximum energy recoverable minus

the minimum demand in the farm. The approximate size is 2 m³.

Cost Analysis

TOTALECO heat exchanger from Ygnis

Break-even: 2.1 years

Pay-back: 1.9 year

NPV after 10 years: £ 15,048.69

Heat exchanger from Bowman

Break-even: 3.3 years

Pay-back: 3.0 years

NPV after 10 years: £ 14,543.84

Conclusion

The Totaleco heat exchanger is then more suitable for the needs of the Farm.

Indeed, even if it is not the more efficient solution, its low price gives

it a big advantage and will make all the installation more profitable.

This will represent an economy of more than £ 200.00 per month.

» Go to Case Study #2: Glycerine Applications