Application of Heat Pumps in Rural Locations

Introduction:

According to the second law of thermodynamics heat cannot spontaneously flow from a colder to a hotter location. Heat pumps move heat from a lower temperature heat source to a higher temperature heat sink in a heating cycle - and vice versa in a cooling cycle - using mechanical work (using electricity to do the work). There is more potential for heat pumps in rural locations, due to the availability of abundant thermal sources like large areas of land, air and water.

Operation:

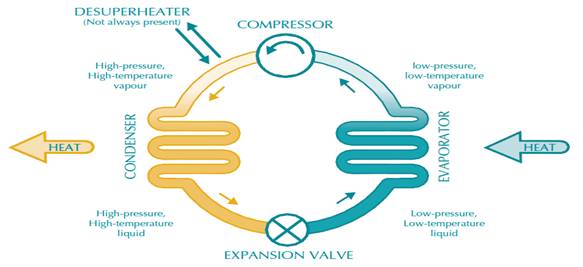

Heat pumps (vapour compression heat pumps) transfer heat by circulating a phase changing substance called a refrigerant through a cycle of evaporation and condensation. A compressor pumps the refrigerant between two heat exchanger coils. In one coil, the refrigerant is evaporated at low pressure and absorbs heat from heat source (ground, water or air). The refrigerant is then compressed en route to the other coil, where it condenses at high pressure and it releases the heat it absorbed earlier in the cycle to the heat sink.

Figure 1. The Refrigeration Cycle (Heating Mode) of a Typical Packaged Heat Pump Unit

Source: Commercial Earth Energy Systems: A Buyers Guide, Energy Resources Canada

Types of Heat Pumps:There are different types of heat pumps, based on the source/sink and nature of operation.

Classification of heat pumps based on source/sink:

Air Source Heat Pump:In Air Source Heat Pumps (ASHP) heat is removed from indoor air and rejected to the outside of a building during the cooling cycle, while the reverse happens during the heating cycle.

In reality, the capacity and performance of air-source heat pumps decrease rapidly with decreasing ambient temperature during heating season, and with increasing ambient temperature during cooling season. Over extended periods of sub-freezing temperatures, as the air source temperature drops below 4°C, there is potential for the evaporators to suffer performance degradation due to ice formation. Since rural areas are more exposed, weather conditions are more adverse and air temperatures are unpredictable or uneven; ASHP are generally less efficient. ASHP are an option only if the local climate is mild or there is a difficulty in earth connection.

Ground Source Heat Pump:A Ground Source Heat Pump (GSHP) is a heating and/or cooling system that pumps heat to or from the ground. It uses the earth or water as a heat source (in the winter) or a heat sink (in the summer). This design takes advantage of the moderate temperatures in the ground to boost efficiency and reduce the operational costs of heating and cooling systems, and may be combined with solar heating to form a geosolar system for greater efficiency.

GSHP is recommended to be considered a priority choice for new constructions, especially for large buildings where the upfront cost is not a pressure to the owners (where the local climate indicates large seasonal variation in temperature and with feasible soil or water conditions).

Ground source heat pumps are split into two categories, based on the earth connection or ground heat exchanger.

Horizontal Ground Heat Exchanger (closed loop):

This type of installation is more suitable for residential purposes due to its cost effectiveness. In this type, the ground heat exchanger is buried at least 1.2 m under ground and runs horizontally to the ground. A typical Horizontal loop will be 120 m to 180 m long per ton of heating - so it requires a huge land space. The heat exchanger may be curled into a slinky shape to fit more of it into shorter trenches, thus reducing the land space required (but this requires more pipes or additional heat exchangers).

Vertical Ground Heat Exchanger (closed loop):

This type of installations is suitable for commercial and residential buildings with large heating and cooling loads. This type of heat exchanger runs vertically to the ground surface; around 45 to 135 meters deep with a U bend at the bottom. Each vertical heat exchanger is connected to a horizontal pipe or heat exchanger connected to the heat pump in the building.

This type of installation is much more expensive, but requires less land space, less piping and less heat exchangers than horizontal ground heat exchangers.

Pond/Lake (closed loop):

This type of installation is the most economical compared to other types of GSHP. In this type, the heat exchanger runs into the water, then long sections are submerged under water at least 2.5 m under the surface to prevent freezing. The water level should never drops blow 1.8 m at its lowest level to maintain sufficient heat transfer.

Pond/Lake (open loop):

In this type of system, ground water from a well or aquifer is piped directly in to the building, where it transfers its heat to a heat pump and then the water is pumped back into a discharge well located at a suitable distance from the intake well. It can be employed cost-effectively if ground water is plentiful and relatively clean. It is simple to install in areas where local regulations permit.

Classification of Heat Pumps based operation:

Mono-valent Heat Pumps:

Heat pumps alone can supply the demand without any auxiliary heating system. This system can supply temperatures up to 65°C for new buildings and retro-fitted buildings with good fabrics, where the demand is mostly uniform over the year.

Bi-valent Parallel Heat Pumps:

Are a combination of two heating systems. Here, heat pumps provide heating independently to a certain point, at which an auxiliary heating system is turned on and the two systems operate in parallel to meet total heating demand. They can supply temperatures up to 65°C and are generally used for buildings with highly varying monthly or seasonal demands.

Usually heat pumps are designed to meet the base load and an auxiliary system is designed to provide the excess or peak demand.

Reference:

- Ruqun Wu, 2009. Energy Efficiency Technologies – Air Source Heat Pump vs. Ground Source Heat Pump, [online]. Vol.2 No.2 Available at:

http://www.ccsenet.org/journal/index.php/jsd/article/view/2986/2757

| MSc: Renewable Energy Systems and the Environment | © University of Strathclyde 2010 |