Introduction

The Buoy solution has been developed as an alternative to the Hydrofoil solution. Whilst the Hydrofoil offers the advantage of introducing dynamic lift to the top of the mooring (thus increasing the mooring angle between the seabed and the mooring line), the Buoy solution offers the advantages of simplicity and cost effectiveness.

The Buoy solution has been developed as an alternative to the Hydrofoil solution. Whilst the Hydrofoil offers the advantage of introducing dynamic lift to the top of the mooring (thus increasing the mooring angle between the seabed and the mooring line), the Buoy solution offers the advantages of simplicity and cost effectiveness.

The size of buoy required was identified, by investigating the relationship between the buoy size and the mooring angle. The loads on the mooring system were calculated, using Excel spreadsheets (for static loads) and Orcina Orcaflex software (for dynamic loads). Various different options were investigated for the Buoy mooring system, including introducing multiple mooring lines, and using a Spar buoy. The impact of the vertical velocity profile on the turbine performance and the Buoy mooring system design was also investigated.

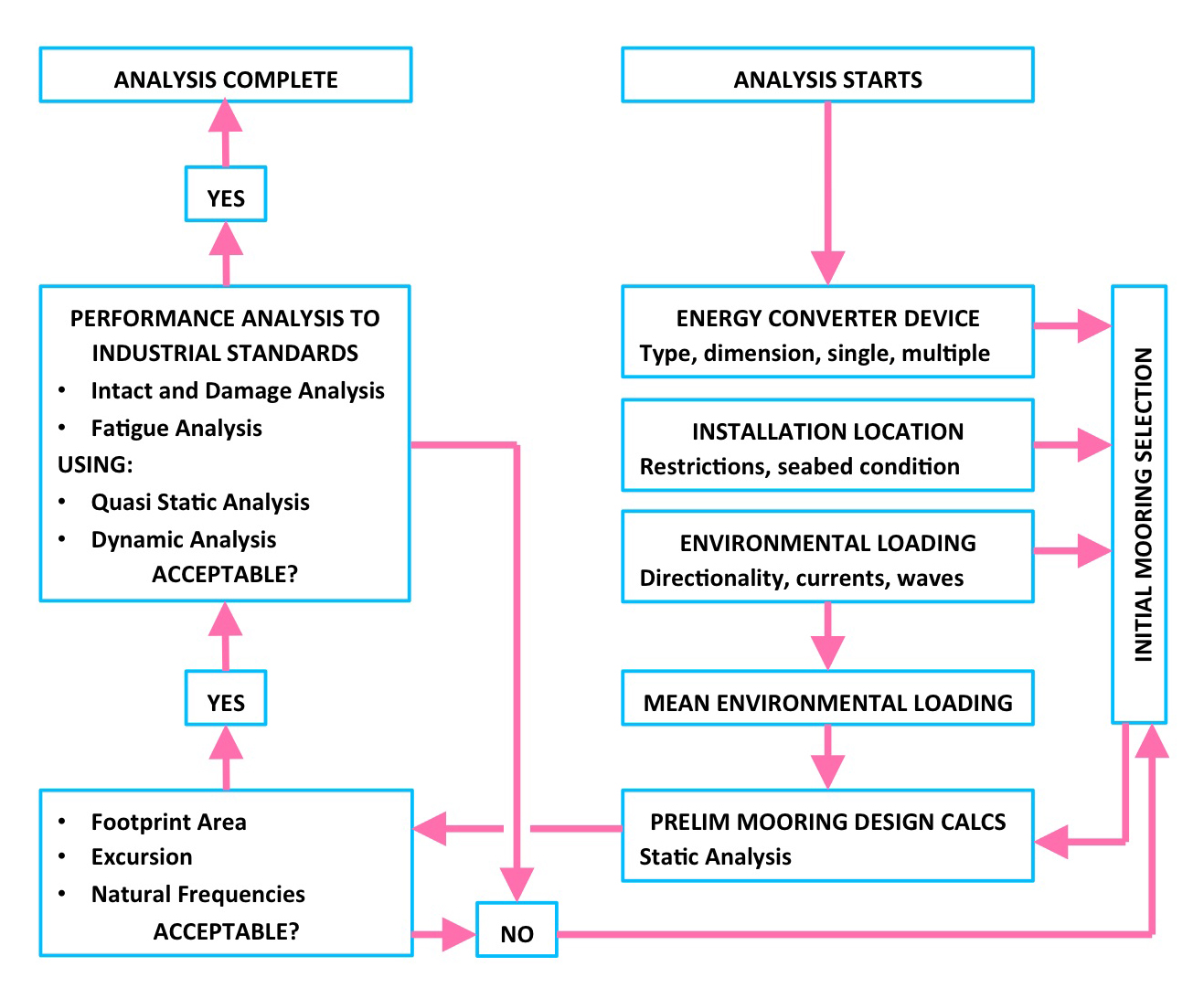

Design Approach

Within the relatively new offshore marine energy field suitable standards for station keeping and analysis methods have to evolve from their applications. However, the standards and analysis methods available from the oil and gas industry may be introduced into the marine energy sector. (Johanning et al., 2006)In order to choose a reliable station keeping system the design needs to be verified by an industrial standard. In the short term this means applying relaxed offshore oil and gas industry standards, such as API (1997) and DNV (2010). For the initial choice of a station keeping system three installation properties must be established in the first instance: (Johanning et al., 2006)