|

As it was described

in the Methodology part of the Project Web Page, once the demand of

the Xscape site is reduced, the analysis of the supply side

can be undertaken. This way a total energy efficiency analysis

for construction villages

can be performed.

In this part of

this project an evaluation of the supply side is conducted

in order to improve the efficiency of the supply as well as reducing CO2 emissions.

In addition, the

use of efficient supply options such as Combined Heat and Power (CHP)

systems and Heat Pumps as well as renewable supply technologies has been studied.

Back to Top

The objectives of this study are to evaluate

alternative supply options for construction villages especially

focusing on Laing O'Rourke's Xscape site.

The alternatives have been studied by considering

different aspects of construction villages and

evaluating the advantages and disadvantages of the different supply options in terms of economic, social and

environmental issues. In addition renewable supply technology that

is most suitable for construction sites shall be identified and

studied in more detail.

The study on Laing O'Rourke's Xscape site will be undertaken by considering the

current supply options: diesel generator and connection to the grid;

as well as the identified renewable solution.

Back to Top

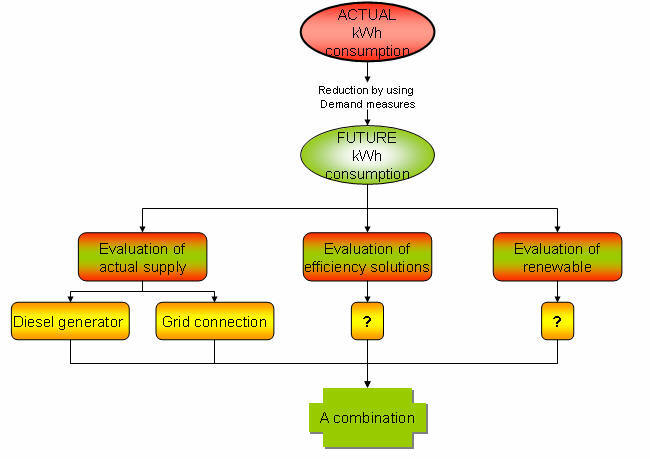

For the evaluation of the supply side, the actual situation

of the supply is analysed using the Xscape site as reference in this

project. The following assumptions have been made for our analysis.

-

The power

output will be calculated by using the actual consumption

records (metering data) and applying the identified demand

reductions.

-

The demand reduction

is estimated according to the Demand Side study of this Project.

The topics studied have been:

-

Actual kWh

consumption

-

Reduction by

using Demand measures

-

Future kWh

consumption

-

Evaluation of

the actual supply: Diesel generator, connection to the grid.

-

Evaluation of

efficiency for : CHP and Heat Pumps system.

-

Evaluation of

Renewable options. RE selection.

-

The efficiency

results: combination of the supply systems.

The methodology to evaluate the supply side is shown in the

above flow chart.

Back to Top

The energy

consumption profile for each construction site varies continuously

and generally increases as a project progresses. The usual

practice of considering the annual energy demand is wholly

inappropriate for the construction business as projects varies in

both time and size.

In most

construction sites Diesel generators acts as a major source for

electricity supply, and thereby constitute to about 75 to 80 % of

the fuel costs. For the remaining one third of the project electricity

is used from the grid. It is important to note that the

carbon emissions resulting from electricity generation by diesel

generator are about twice those of mains electricity.

Electricity is used for space and water

heating, lighting and

electrical offices and catering equipment. A deep analysis of the energy use and the power installed

can be followed at the demand side analysis of this web site.

The profile of the supply is as following.

A)

In

terms of used devices:

The electricity required is obtained from a diesel generator

and directly from the grid through a grid connection.

B)

In terms of costs:

Following the figures we have obtained from Laing

O’Rourke, it can be estimated that the average expenditure in energy

(diesel and electricity) from a typical construction site could be

about £126,000 per year. Note that depending on every

company and every provider contract prices for fuel and electricity

from the grid could be different.

Although data for electricity consumption were obtained

for the Xscape

site those values can not be shown on this web site for

privacy reasons. Due to this the average value are assumed as the

energy expenditure on the Xscape site.

-

The diesel generator contributes to 88.16% of the

total cost of energy supply.

-

The electricity from the grid is about the 11.83% remained.

C)

In terms of time:

Along the project

duration the supply of a construction village is

typically

structured into the following periods.

-

2/3 parts of the project: supply by

diesel generators.

-

1/3 parts of the project: grid connection.

Back to Top

On almost all the construction villages, there is a

possibility to use temporary power supply from the grid. In order to connect to the grid some considerations must be

followed:

-

The dates

and other key programme dates

-

The location

of existing supply lines

-

Local and

seasonal environmental considerations

-

The

evaluation of the existing supply companies

-

The

evaluation of the different quotations, contracts and security

of supply from every company.

-

The

definition of the supply voltages required.

-

The earthing

requirements and proximity to communications equipment

-

The siting

and protection of metering, switchgear, distribution boards etc

-

The correct

rating of fuses and switchgear for safety and plant protection

-

The

arrangements for controlling, operating and maintaining the

system

-

The

provision of lockable switches and means of isolation

-

The

commissioning and handover arrangements

-

Future

modifications or extensions to the temporary supply system

Using some information obtained from experienced civil

engineers as well as referring to the Site Layout part of this web

site, it can be said that grid connection is not made until roughly

two thirds of the project is

because of the need to keep the electrical supply options flexible.

Temporary facilities are often moved around on site and diesel

generators are ideal for shunting around with the facilities.

Although ideally they should not be moved as this costs money and is

inefficient, it usually happens because of external uncontrolled

conditions and/or sometimes poorly planning. Furthermore, the connection

into the grid is delayed in order to reduce the risk of accidents by

damaging the electricity connections during the buildings

activities.

It is estimated that it takes between two to four weeks to get a

high capacity connection to the national grid. The electricity

from the grid is purchased at 7-8 p/kWh.

Back to Top

As it has been

shown in previous chapters of this report, power for the Xscape site

at the time of this study was provided mainly by a diesel

generator. The diesel generator supplied 66% of the electricity over

the whole project duration which incurred 80% of the total

electricity costs.

On the Xscape, a 200kVA generator is used to provide

electricity for lighting, space and water heating, office and catering

equipment in the site accommodation. A 27kVA generator is used

to supply electricity primarily for temporary lighting with some

subcontractors using this generator for their power tools.

Diesel

generators are the preferred

supply

systems on

sites mainly due to flexibility reasons as well as the ease of

obtaining the fuel supply. Nevertheless, some

problems are detected regarding diesel generators.

Every company has a different contract for their oil price but an

average of 20p/litre is considered as a good approximation of a

fixed oil price. Thus, at 35% maximum

generator

efficiency, the price of the diesel is estimated at 5.76 p/kWh.

However

the price of fuel varies in huge ranges and can be said to

increase significantly in the near future.

The efficiency of the generator is an important aspect to be

considered. The efficiency shows the relationship between the energy

use and the total power output from the generator.

On of the main problem is that diesel generators are mostly

operated only on part of their load. Following the curve shown in the

following figure,

the efficiency of a diesel generator is strongly related to the

load. Thus, with decreasing generator load the efficiency is

reducing accordingly. On the Xscape site the load of the generator is fixed at the

35.5% what means an efficiency of the 30%.

The lower the efficiency of the diesel

generator the higher is the amount of CO2 emitted by the

generator. Hence, at a load of 35.5% the

CO2 emissions from the generator are 0.72 kg/ kWh, which

means almost a 70% of

increase with respect to the standard of 0.43kg/kWh

CO2 applying to the

national grid.

Thus, electricity

produced by the generator is not more expensive than the electricity

purchased from the grid, the associated CO2 emissions are

extensively higher. This

shows that an alternative must be developed to reduce the CO2

emissions by improving the generator efficiency or by reducing the

generator use.

|