Solar Collectors

How does a

solar collector work?

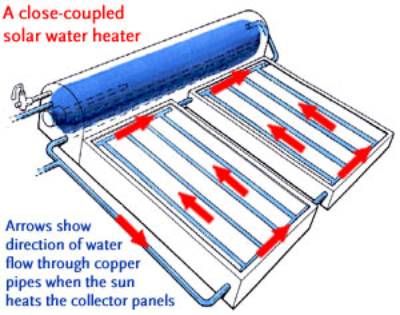

A solar collector is basically a flat box and are composed

of three main parts, a transparent cover, tubes which carry a coolant and an

insulated back plate. The solar collector works on the green house effect

principle; solar radiation incident upon the transparent surface of the solar

collector is transmitted through though this surface. The inside of the solar

collector is usually evacuated, the energy contained within the solar collect

is basically trapped and thus heats the coolant contained within the tubes. The

tubes are usually made from copper, and the backplate is painted black to help

absorb solar radiation. The solar collector is usually insulated to avoid heat

losses.

Active solar water heating

The main components on an active solar water heating system

are

- Solar

collector to capture the suns energy and to transfer is to the coolant

medium

- A

circulation system that moves the fluid between the solar collector and

the storage tank

- Storage

tank

- Back

up heating system

- Control

system to regulate the system operation

The two main types of solar water heating systems are the

closed loop system and the open loop system. The open loop system used water as

the coolant, the water circulates between the solar collector and the storage

tank.

There are two main types of open loop system these are the

draindown system and the recirculating system, the main principle behind both

systems is the activation of circulation from the collector to the storage tank

when the temperature within the solar collector reaches a certain value.

In the drain down system a valve is used to allow the solar

collector to fill with water when the collector reaches a certain temperature.

In the recirculating system water is pumped through the

collector when the temperature in the storage tank reaches a certain critical

value.

In applications where there is likely to be a temperature

drop below zero degrees then it is necessary to use a closed loop system. The

main difference between the open loop system is the water is replaced with a

coolant which will not freeze in the tempeture range which the solar collector

may be subject to. The coolant will usually be refrigerant, oil or distilled

water. Closed loop systems are generally more costly than their open loop

counter parts and great care must be taken to avoid contamination of the water

with refrigerant. The energy captured by the coolent is then transferred to the

hotwater via a heat exchanger. In a

drainback system the coolant may be distilled water. The system works on

the principle that there is only water in the collector when the pump is

operating. This has the benefit that the coolant used in the sytem will not

have the chance to cool down during the night when temperature may drop to a

level which may cause the coolant to increase in density and thus perhaps cause

is not be as free flowing as it should. The only necessary feature on the

drainback system is that the solar collector are elevated from the heat

exchanger or drainbak tank in order for the coolant to flow out of the

collector. This sytem again workson the principle that the water is circulted

between the collector and the drainback tank when the designated temperature is

reached between the solar collector and the hot water.

Active

solar space heating

The system components in a space heating application are the same for water heating with the addition of radiators for space heating or under floor heating coils or even forced air systems.

A radiator system will generally work in a very simmialr

mannor to the hot water application, the main deffernece is the inclusion of a

boiler, heated water from the collector is passed through the heat exchanger or

drainback tank and is then passed to a boier with is used to supplement the

water hearing requirements before passing into the radiators to be used for

spaceheating.

Air distribution systems.

Again the air distribution system works in a manor very

similar to the hot water system, the main difference is the inclusion of a

blower and an air duct. The system uses an additional controlled which will

allow air flow over the coil when the temperature in the storage tank is high

enough that passing air over the coils in the return duct of the apparatus will

allow the system to make a positive contribution to the heating space heating

demand.

In large commercial or industrial applications system design

is slightly different from residential applications. It is worth noting that

the temperature rise across a collector is fairly constant to use an example if

the temperature of supply to the collector is around 60°F and the

temperature of return is around 73oC or the return is 173°F and the

supply is 160°C, this

basically means that high and low temperature applications should not be put in

series inside a loop. The low temperature application would basically drag down

the higher temperature application. Vacuum collectors are excellent performers

in high temperature applications the collector loop should be dedicated to the

higher temperature application until the load is satisfied. In applications

such as for hospitals, hotels or commercial office blocks is may be necessary

for the installation of two or more tanks connected in series.

1. storage tank 2. preheat tank 3. cold feed 4.mixing valve

5. supply and return to collector 6. hot water out

system operation: Hot water from the collector passes

through the coil in tank one (1),

Then, depending on it's temperature, it is diverted by a three way valve (4)

to either: the coil in tank (2) if it is above the set

temperature, (meaning tank (1) is hot) or the collector, if it

is below the set temperature of the mixing valve.

Commercial and industrial design considerations: The system

can be expanded to include more than one preheat tanks, the heat exchange coils

are linked by three way valves and the water which is to be heated runs in

series through the tanks in the opposite direction. The three way valve can

either be thermally controlled or electrically operated. No more than 100 tubes

should be plumbed in series. Care must be taken when designing the pipe work in

each section to ensure that each section receives equal flow.