CATALYTIC

FLAMMABLE GAS SENSORS

The

concept of the pellistor is based on the fact that the most foolproof

way to determine whether a flammable gas is present in air is to test

a sample by trying to burn it. A pellistor consists of a very fine coil

of wire suspended between two posts. The coil is embedded in a pellet

of a ceramic material, and on the surface of the pellet (or 'bead')

there is a special catalyst layer.

ELECTROCHEMICAL

SENSOR TECHNOLOGY

The

carbon monoxide sensor consists of three electrodes immersed in a liquid

electrolyte (a non-metallic liquid that conducts electricity, usually

through acids or dissolved salts). The three electrodes are the working

electrode, the reference electrode, and the counter electrode. The most

important of these is the working electrode (WE). The working electrode

is made of platinum, which is a catalytic metal to CO (it catalyzes

the oxidation of CO to CO2), backed by a gas-permeable but hydrophobic

(water-proof) membrane. The CO gas diffuses through the porous membrane

and is electrochemically oxidized (Equation 1).

CO

+ H2O à CO2 + 2H+ + 2e -------------------------------------------------------(Eq.1)

The

electrons involved in the electrochemical reaction flow from the working

electrode through the external circuit, producing the output signal

of the sensor.

SEMICONDUCTOR

SENSOR’S THEORY OF OPERATION

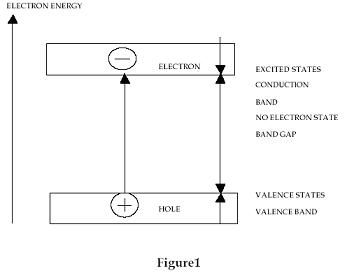

One

of the important properties of a semiconductor is the concentration

of charge carriers. As semiconductors in general contain relatively

few free charge carriers this facilitates control of their behaviour

and concentration by external means. In a clean semiconductor, negative

free electrons and positive free holes are present in equal numbers.

These electrons and holes are created by the thermal excitation of valence

electrons from the valence states, in the crystal, to the conduction

band leaving behind positive holes in the valence band. (See Fig1.)

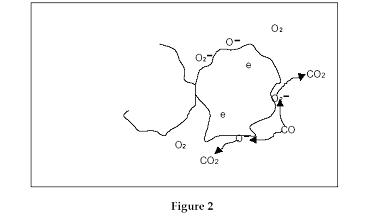

This

is true for a so-called ‘intrinsic’ semiconductor, for a pure oxide

system, and is equally true for Silicon or Germanium. For most commercial

applications of semiconductor materials it is necessary to add a dopant,

which supplies an excess of holes or electrons that form the majority

current carrier, i.e. p or n type semiconductors. For the Chrome Titanium

oxide system, Chrome oxide is the intrinsic semiconductor, which, with

a valency state of 3+, when doped with Titanium, of valency 4+, now

becomes a p-type semiconductor. The Titanium requires an extra electron,

which it takes from the Chrome d-band leaving a hole.

The electron it takes is trapped by an oxygen atom forming

TiO2.Therefore Oxygen adsorbed at the gas–solid interface removes electrons

from the surface region of the solid to form a surface oxygen ion; the

oxygen can be thought of as a surface trap for electrons from the Chrome

oxide d-band (see Fig 2).

Therefore

the adsorbed oxygen gives rise to an increase in the hole concentration,

and it follows that any decrease in the surface coverage

of Oxygen ions by reacting with, for example, CO to form CO2 would release

electrons back into the lower band and decrease the hole concentration

and hence lead to an increase in the resistance of the semiconductor

material.

|