top

Contrary

to what some might believe this type of forestry does not involve cutting

down rainforests and ancient woodlands. It is a technique initially used in

Sweden. Coniferous trees are planted at high density and after a period of

growth selective cutting reduces the density of trees. The thinning produces

wood chip that is later used for various purposes.

top

Short

rotational arable coppicing, is currently viewed by some as a potentially

important source of fuel for electricity generation in Scotland and the UK

- the UK Governments Department of Trade and Industry estimates (Energy Paper

62) that the maximum total realistic UK resource potential by 2025 could be

up to 150TWh/yr - half the current UK electricity demand! Some farmers already

burn straw in special plants used on their farms for power. Over the

last couple of years, there has been great debate over the future of energy

crops in Scotland: whether or not it makes sense to utilise agricultural

land, especially ‘set aside’ land to grow an energy source for the future.

Currently farmers get paid for ‘set aside’ land as part of government subsidies

and it appears to make far more sense to grow energy crops rather than pay

farmers for doing nothing.

Crops

tend to be established by planting cuttings in cultivated ground. Coppicing

occurs every 2-4 years when stems are harvested by cutting 5-10cms above ground

level (cutting cycle). Cutting cycles can vary depending on the objectives

of management and available land - research indicates that a yield increase

of up to 70% can be achieved for one 4-year rotation compared with two 2-year

rotations grown over the same periods.

Energy

crops include

· Willows

· Poplars

· Hemp

· Miscanthus: a temperate climate grass adapted to moist soils (sewage

sludge can be used as fertiliser for this plant)

· Maize

· Sorghum (a grass like grain crop that produces sugars)

Willow

has been the main tree species highlighted for SRC - poplar may also be used.

This is because willow is an ideal species to grow in the Northern hemisphere,

mainly in cold and wet areas. It produces large amounts of biomass in relatively

short periods due to its fast growing nature. It is reasonably simple to establish

and requires low input of agricultural chemicals during its growth. Willow

will thrive in a wide range of soil types and can be grown from cuttings provided

there is an adequate water supply (and as far as “sunny” Scotland is concerned

this does not pose a problem). Care needs to be taken to control weeds and

protect new plantations from rabbits and deer. During growth the use of fertilisers

and chemicals is lower than for most agricultural crops. The willow can be

cut back at the end of the first year as this encourages growth of multiple

shoots, alternatively plantations could be removed and the land returned to

agricultural crops if things are not going as planned. Yields from coppicing

can be stored until needed and then used to generate heat and electricity.

So

far SRC does not appear to carry much wait in terms of economic viability

- this is improving. Prices will have to fall in order to become a real option

for the future or the level of subsidies will have to increase in progress

is to be made.

top

Forestry

residues are produced when controlled thinning of plantations and trimming

of felled trees is undertaken to reduce forest fire risk and to accelerate

the forest growing rate that can sometimes be prevented if the area is overpopulated.

This waste is usually just left to rot on the forest ground; extracting and

collecting it clears up the forest making it easily accessible and manageable.

In this category waste from public gardens and woods can also be included.

The waste can be collected, dried and used as fuel.

top

These

include straw, manure, vegetables, fruit and general garden waste. Until recently

the excess straw produced in the UK was burned in the fields or ploughed back

into the land. As of the end of 1992 environmental legislation put in place

has restricted field burning and thus straw has been seen as a potential source

of energy. Other residues include potatoes and sugar beet tops as well as

damaged fruit and around 5 million tonnes of nursery wastes. Using agricultural

residues as a source for energy tackles another problem apart for the need

to find alternative energy sources. Agricultural residues include animal wastes.

Use of these wastes reduces the possibilities for odour and water pollution

by manures. Manures from cattle, chickens and pigs are the most common ‘wet

wastes’; in the UK about 7 million tonnes of such wastes are produced in a

year!

top

Various

plants have seeds that can be crushed on the farm to produce a range of vegetable

oils and although they are not good enough for human consumption they can

be used to power motors and onsite generators like those used for combined

heat and power plants (CHP).

top

One

of the main sustainable development issues in Scotland is the effective management

of waste. Waste disposal sites are a source of pollution, in terms of emissions

to the atmosphere and water and are associated with health and environmental

effects. Ultimately, the goal is to reduce waste production and to maximise

recycling and reuse. But the waste that is produced needs to be dealt with

effectively and sometimes energy generation is the optimum choice due to technical,

geographic or market barriers to recycling.

Energy

can be generated from the vast amounts of municipal and industrial waste that

society produces.

top

This

is waste that relates to a city or town, therefore it is wide ranging in composition,

for example:

· Paper and paper products

· Plastic

· Rubber and leather

· Textiles

· Wood

· Food wastes

· Yard wastes

· Glass and ceramics

· Metals

· Miscellaneous (including

even fridges!!)

This

can cause problems when the waste is incinerated as different elements burn

at different temperatures and speeds, leading to an uneven mixture and some

waste not being completely burned. This means that energy is not extracted

as efficiently as possible. Scotland creates 3 million tonnes per year of

MSW, 90% of which goes to landfill, 5% to recycling and reuse, and 5% to incineration

(DETR, SEPA). Incineration is therefore a small part of waste management for

Scotland when dealing with MSW. In the long term, this picture will change

and Scotland will follow the European example of countries like Denmark, where

at present 60% is recycled, 35% to EFW, and 4% to landfill. The EU Landfill

directive aims to divert wastes from landfills and will also influence the

increase in the number of incinerators. These will all be part of a grand

picture where recycling, reuse and EFW all work together to deliver an integrated,

sustainable waste strategy.

top

Waste

from timber processing is a great source of biomass feedstock. Dry sawdust

and offcuts usually thrown away after the processing o cut timber make exceptionally

good fuel. The furniture industry in the UK is estimated to produce 35,000

tonnes of such residues a year!

top

To

date, one of the key characteristics of fossil fuels are that they can be

easily acquired, transported and stored for use without their intrinsic energy

content being compromised. This means that in order for biomass to be a competitive

rival to fossil fuels it should be transportable and readily available for

use. Unfortunately this is not as easy as it may sound; biomass is wholly

organic and thus has a short shelf life by nature. For example the water content

of biomass does not contribute to its stored energy. Water contents can be

as high as 95% for fresh plants! This means that only 5% of the plant has

energy to be tapped into. Further more if the matter is not dried then decomposition

sets in quickly and renders the feedstock unusable. This means that in order

to use biomass it has to be dried to reach water content of about 20%.

In addition transporting biomass resources poses a problem i.e. they have

to be processed in such a manner that aids transportation. For example if

plant matter is dried and then chipped not only will burning it be made easier

but transporting will also be simple.

top

As

stated above biomass is a mixture of organic compounds and whatever form it

comes in it must be used within a short period of time on site (otherwise

it must be processed so that it’s shelf life is extended).

This

physical processing involves:

· Removing the moisture

(This can be achieved by in-situ drying facilities)

· Chipping or creating

fuel pellets (Chippers can be placed next to dryers to prepare the feedstock

for transportation, storage or immediate use).

An

example of physical processing is:

This is a result of processing MSW, facilitating recycling, re-use and ensuring

the homogenous nature of the waste. The non-combustible elements of the waste

are left over after processing, giving the waste a higher calorific value.

The new improved composition of the waste allows increased efficiency from

incineration and reduced emissions and products as the waste that creates

the harmful effects can be removed during processing. Said processing involves

· Separating unwanted

components (for example by magnetically extracting ferrous metals)

· Shredding

· Drying

· Compacting the material

into pellets

This

type of conversion allows for and otherwise very cumbersome fuel resources

to become easily transported and more hygienically handled, it also allows

incineration to play a part in waste management where reduction, reuse and

recycling can be maximised.

top

Further

processing has also been developed; the end product is called densified

refuse derived fuel (d-RDF). This is a process by which the combustible

part of the waste is separated, pulverised, compressed and dried to produce

solid fuel pellets about 5cm long.

top

In

order to produce bioenergy various processes can be used to convert the intrinsic

chemical energy of biomass directly to heat or electricity or to the intermediate

biofuel. Biofuels include Methane Gas, Liquid Ethanol and Methanol

or Solid Char or Charcoal.

top

All

fuels contain two combustible constituents; the volatile matter and

char. As the temperature of the fuel rises the volatile matter is released

in the form of vapours or vaporised tars and oils. The spurts of flame, for

example as wood burns, are an indication of the combustion of these products.

After

this process (which is known as thermal degradation) ends the solid remnants

comprise of char and inert matter. The char, which is mainly carbon, can be

further combusted to produce heat and CO2. The inert matter then

becomes clinker, slag or ashes.

Most

of the bioenergy is within the initial volatile matter. This means that any

furnace designed to burn biomass fuels should be designed in such a way to

ensure complete combustion of these vapours. In addition, air must reach all

of the char; this could be accomplished if small pieces of the matter are

burnt (another reason behind the need to physically process biomass before

it’s use)

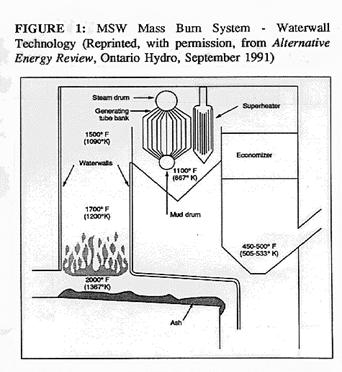

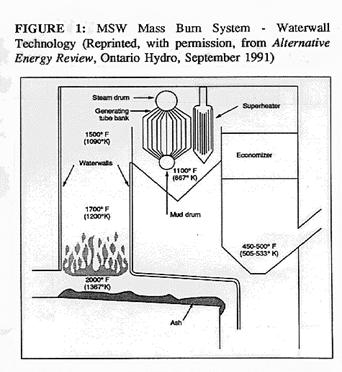

The

following diagram illustrates how combustion can be used to produce energy:

Mass

Burn Combustion (MBC) can use municipal Solid Waste (MSW) to generate electricity.

This is one of the main methods of incineration and has been around for years.

It is commercially available and has been optimised. The plant operates by

feeding waste onto a moving grate where it is burned; the heat generated by

this is used to generate steam that drives a generator to produce electricity.

The burning of the waste produces two types of ash. Incinerator Bottom ash

falls through the grate for collection and is either landfilled or used in

the construction industry. Fly Ash, which escapes with the flue gases that

are emitted to the atmosphere, can contain sufficient dioxins and metals that

require cleaning. As it involves the mass burning of MSW; this has many concerns

attached to it.

In

particular the waste is a mixture of different materials if these are combusted

they may have a detrimental affect on the environment. The main pollutants

that result from MSW incineration are as follows:

· Gases

· Metals

· Organic Substances

· Particulate Matter

The

main area of concern is the contents of the array of gases that are emitted

from the plants. The gases contain dioxins, which are suspected of causing

many health problems including cancer. The particulate matter is also an area

of concern, focusing particularly on ultra fine particles less than ten millionths

of a metre. These are often inorganic materials with metals and organic compounds

on their surface. In Scotland, all releases to the environment are regulated

by SEPA, the Scottish Environmental Protection Agency.

top

This

method of incineration uses RDF and is an alternative to the mass burn system.

The pellets are fed onto a bed consisting of a mixture of sand and dolomite

mineral. Air is then pumped through the whole mixture to create a bubbling

liquid. The waste in this new liquid form has an improved combustion efficiency

that reduces pollution and increases generation per ton of waste.

A

downfall of this technology is that it is slower than MBC and there is limited

experience. This form of incineration though has not yet been proven on a

commercial scale and requires further investigation.

top

Two

techniques that are very promising for the future of waste incineration are

Gasification and Pyrolysis. These technologies are not as developed as MBC

but promise many benefits. The two techniques have very similar economic characteristics,

there is an option of pressurising the gas, which increases the capital costs

but is compensated by cost savings at generation. The savings are created

as compression of the gas is no longer required and there is higher system

efficiency.

top

The

gasification process in general involves the reaction of a solid fuel with

hot steam and air (or oxygen) and the subsequent production of a gaseous fuel

by partial oxidation. The diagram bellow illustrates the process. Gasifiers,

depending on their type can operate with temperatures varying from a few hundred

to over a thousand degrees Celsius and from pressures from around atmospheric

(1 atmosphere) up to 30 atmospheres.

· The gas resulting

from this process mainly consists of:

· Carbon monoxide (CO)

· Hydrogen (H)

· Methane (CH4)

· Carbon dioxide (CO2)

· Nitrogen (N) The

proportion of the gases in the mixture depends on the processing conditions

and whether air (78% Nitrogen, 20% Oxygen and 2% of others) or oxygen was

used.

The

simplest of gasification processes result in gases containing up to 50% by

volume of CO2 and N. This means that the fuel has a low energy

value so transporting is not economical viable but on site use can prove to

be beneficial. There are benefits to using such a complicated process

to produce energy from biomass. The resulting gas is cleaner and more versatile

than the original biomass; any unwanted pollutants can be removed during processing.

top

Gasification

using oxygen instead of air produces a mixture of gases containing Hydrogen,

Carbon Monoxide and Carbon Dioxide. Removing the CO2 produces a

mixture called Synthesis Gas, this gas can then be used to produce

almost any hydrocarbon. The most common products are methane and methanol.

Methane is a combustible gas that can be used to drive generators although

it is a very dangerous and harmful greenhouse gas. Methanol is a liquid fuel

that is a direct substitute for gasoline

top

This

age old process, otherwise called destructive distillation, involves

the heating of the original biomass in the near absence of air, the temperatures

at which this occurs range from 300 to 500 degrees Celsius. These high temperatures

drive the volatile matter out of the original material, what is left is the

char (charcoal). The usual biomass material used for pyrolysis is wood but

nutshells and MSW can be used as well.

top

Further

technological advancement in this sector has lead to a process called fast

pyrolysis. This involves the collection of the volatile matter and depending

on the temperature of the process these materials can be combusted. This liquid

product has the potential to be used as fuel oil. Temperatures range from

800 to 900 degrees Celsius. Fast pyrolysis can leave as little as 10% char

and can convert as much as 60% into a gas.

Gasification

and Pyrolysis have very similar costs but these are again hard to measure

for the sake of generalisation or comparison as they are site specific and

there are no large plants to use as an example. They do promise improved efficiencies

and lower environmental mitigation costs with relevance to MBC. Furthermore

if pressurised gas is used to drive a turbine then this increases capital

costs but leads to a saving in terms of generation due to higher system efficiency.

They allow improved combustion due to the intermediate fuel that is produced

and have lower emissions due to lower gas flows. The production of this fuel

means that it can be transported for generation at a different site. To further

the technology and to make it economically viable, more funding for research

and development is necessary, as well as the financing of the first large-scale

commercial plant.

top

Anaerobic

digestion occurs in the absence of air, the decomposition in this case is

caused not by heat but by bacterial action. Any organic substance can become

subject to anaerobic digestion so long as there are warm, wet and airless

conditions. For example ‘marsh gas’ is a product of the anaerobic digestion

of vegetation at the bottom of ponds, this gas rises to the surface and bubbles,

it is also combustible. With the aid of human intervention there are two products

of this process, biogas and landfill gas. The chemical processes behind the

production of these gases are very complex. The figure below shows the generalised

process.

top

Biogas

is generated from concentrations of sewage or manure. These are usually in

the form of slurry comprised mostly of water (almost 95%). The slurry is fed

into a digester, this input can be continuous (usually the case with sewage)

or in batches. The digestion continues from about ten days up to weeks. The

temperature in the digester should be kept at 35°C and although the digestion

itself produces heat, in colder climates some top up heat should be provided.

In order for the process to remain sustainable the excess heat should be provided

by the biogas itself. In the very extreme cases all the produced biogas

has to be used for this heating. In these cases the process is still beneficial

as it offsets the need to use fossil fuels in order to process the wastes.

top

As

already stated a huge proportion of the waste produced in Scotland goes to

landfill sites. As this waste sits under the ground in these sites, the biodegradable

organic matter within the waste goes through anaerobic decomposition and produces

a gas that is roughly an even mixture of Carbon Dioxide and Methane. This

is an explosive mixture and has been known to cause explosions under ground.

This gas used to be flared off or released to the atmosphere. The combustion

of this gas reduces net emissions of carbon dioxide if used to offset generation

from fossil plants as less is produced. This represents a small resource,

but it is economically competitive with other forms of generation and it can

provide base load electricity output.

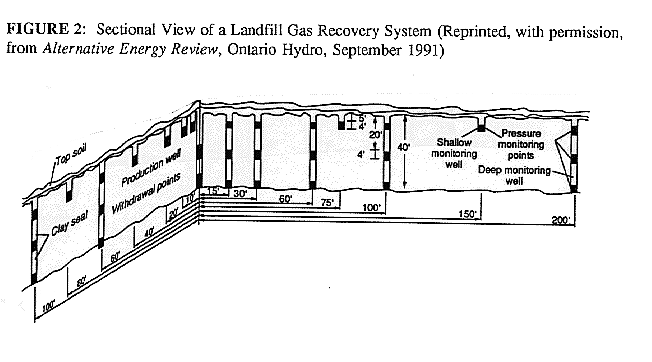

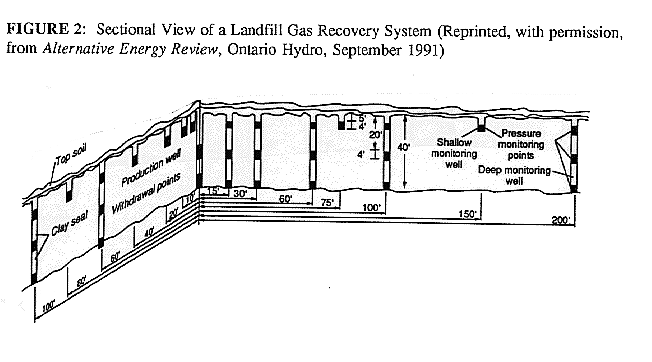

The

length of time and amount of gas that is available from a landfill site is

very specific to the type of waste, moisture content, temperature, acidity

and the design of the site. As the diagram above shows, gas is drawn up from

vertical or horizontal wells through a system of pipes. At this stage the

gas is usually warm and saturated with moisture. The extraction pipes contain

condensate traps and are laid at an angle so that as the gas cools, the moisture

does not hinder the flow of the gas. The condition of the gas is specific

to what use it will be put to. The plant is constructed so that there is no

leak of gas to the surrounding land or air. This methane and CO2

mixture can be used in the same combustion process discussed previously. The

generation equipment is usually contained within the same area as the extraction

plant. This site is usually away from urban sites due to safety reasons and

amenity.

top

Fermentation

is also an anaerobic process. With this process Sugars with the use of micro

organisms (usually yeast) are converted into ethanol. Ethanol can be used

as the fuel in the combustion processes. This can either be achieved through

mixing the ethanol with gasoline or by using it directly in some modified

combustion engines. Sugar cane undergoes fermentation most efficiently. Other

feedstock’s can be used such as potatoes and corn, but these require processing

so that the starch can be converted to sugar.

top

The

best way to sum up the various uses of Biomass and the processes involved

in its harnessing is to sum up the products that can be created from the feedstock

and to illustrate there uses (see figure below). So from all of the available

biomass feedstock that can be harnessed and through the various processes

the products include:

· Heat (that can be

used to heat water for use or central heating and to produce steam for use

with steam turbines)

· Gas (to be used to

drive gas turbines)

· Char that can be

burned to produce heat again

· Oil (for burning)

· Straw (again for

burning)

· Ethanol (to be used

as is or mixed with gasoline)

· Methane

· Methanol (to be used

as fuel for especially converted engines)

![]()