[Small Scale]

Introduction, Wind, Land Renting, Case Study, Water, Solar, Biomass, Energy from Waste, Diversification, Economics

![]()

In this section the opportunities

available in the small-scale marketplace will be investigated.

The deployment of renewable technologies at a small scale has large possibilities

for the future, in the same manner as the large scale but to a smaller

degree.

Mainly small-scale applications are associated with a rural environment where a farmer or landowner has the ability to deploy renewable technologies on their land. In this case there are many options available to the landowner to utilise renewable energy technologies.

The use of small wind turbines is becoming increasingly common is generating power for remote locations. Several companies in the UK specialise in supplying small wind turbines especially for this purpose. Some of these companies are Proven, Marlec and Ampair. The experience and knowledge of these companies are increasing all the time and will continue to do so as awareness rises to their possibilities.

Proven wind turbines are finding more widespread applications and more

importantly getting into the public domain. The top image shows a single

turbine used to generate and supply electricity to the building on the

left of the picture. The image above shows the island of Taransey where

the BBC filmed the program Castaway. The 2.5kW Proven turbine can clearly

be seen and was used to supply power to the 'castaways' for the duration

of their stay on the island. The wind turbine on the island stored power

in a battery bank and then supplies AC electricity to the houses through

an inverter.

The above images show turbines manufactured by Ampair and Marlec. Installations

mare located on the small island of Eigg off the west coast of Scotland

and a turbine installed in a holiday home in Norway.

Wind turbines in small-scale applications are becoming more and more frequent. Most small-scale systems utilise battery storage facilities and then an inverter to provide ac electricity from the turbines.

In order to set up a small scale wind turbine there are some checks that need to be done.

Work out the power requirements

on the location.

Speak to manufacturer and get advice on best product

Purchase turbine, batteries, controller and inverter

The system is installed as shown below.

![]()

The turbine generates the electricity.

The controller monitors the battery capacity and ensures they are not

overcharged.

The battery bank stores the electricity in dc.

The inverter converts the dc to ac.

All these components are available to by from each supplier and are essential for a successful installation.

An indication of installation costs will be made using products from Marlec and their current price list.

The costing provided above only shows the costs for parts required. On

top of this price will be the cost of wiring and actual installation.

The installation cost will vary from each installation, so no real estimate

could be made of the cost.

The turbine mentioned above is the Rutland 913 from Marlec. It can be supplied at either 12 or 24Vac. The device is quoted at supplying 6A (12V) @ 10m/s. Therefore it is rated at 72W. The machine does not have a wind speed cutout but rather a thermal cutout when the generator overheats. This machine would provide 630.72kWh/annum if windspeed stayed constant at 10m/s.

If a landowner is fortunate to own a portion of land on a good location for a wind farm they can generate an income without having to do very much. Assuming that their land is in a good position for a wind farm a large company who would like to site a wind farm on this location may approach them. The farmer can then rent the land for the turbines to the company and generate an income from them and still utilise over 90% of the land for animal grazing.

In this case the landowners cannot do much about it themselves, the company will approach them and then they can take it from there.

Many people would like to become self-sufficient in providing their own electrical needs and the application of utilizing small scale renewable technologies can help reach this goal. All of the renewable energy technologies mentioned in this website could be utilised in a small-scale manner. The most obvious and most utilised ones are wind, solar and biomass but depending on location there is no reason why small-scale hydro or tidal generation schemes couldn't be set-up.

In order to fully see the possibilities of such small-scale applications a Case Study of an existing site is the best way.

Small-scale wind installation in Dartmoor National Park produced by ETSU

for the DTI in 1995

The owner of the house lives in Dartmoor National Park, Rundlestone, Devon. This is a remote location with his nearest neighbour approximately 0.5km away and the nearest electrical network connection point is approximately 1km away. Electrical needs had provided with the use of a small diesel generator prior to 1992 but this proved to be unreliable for the duration of the year. The cost of being connected to the national grid proved to be prohibitively expensive, with the owner and his 2 closest neighbours having to pay in excess of £60000. The location is good for generation from a wind turbine and a 2.2kW turbine with blade diameter of 3.4m was mounted on a 6.5m mast. The turbine was located approximately 25m from the house. The system uses a turbine provided by Proven and utilises the system mentioned above with a battery bank and inverter. The installation cost £5000 including all electrical connections.

House and the Proven Turbine.

The full case study and others can be found on the DTI website. http://www.DTI.gov.uk

Depending upon location water can be used in a similar application to that as the wind to generate electricity. There is no reason that the same type of installations used for Hydro and tidal stream could not be utilised for a small-scale single user. This type of installation would require to be catered to the specific site and purpose built.

To utilise the power of water there are some available products from the same suppliers mentioned above for wind. The devices are used to generate electricity from the flow of water. The devices shown above left above are available from Ampair.

The water generators are submerged in the flow of water where the blades are rotated in the same manner as a wind generator. Ampair say that the machines will generate at water flows under 1m/s and can generate up to 8amps at 12volts (therefore they are 96W machines). The devices can be submerged up to 10m below the surface and all electrical connections are sealed and ready for connection to the controller using the same layout as the wind charging system. They are available from Ampair in either 12 or 24Vdc and cost £583.00.

More specialist and higher power devices are available from Proven for hydro operation. Proven acknowledge that no hydro installation is the same and that all are unique, but they claim to have developed a hydro turbine that can adapt well to almost all types of hydro installation. Using computer software and laser cutting technology does this. The image above right shows a 6kW, 35m head stainless steel turbine runner.

The problem with water flow is that it is similar to that of air - constant

variation during the year. All water turbines have operating difficulties

with variable flow. The turbines are usually purpose built to deal with

a specific water flow, with any other flow rate the efficiencies drop

quite drastically. In order to create an efficient system over a wide

range of water flow rates the jet of water entering the turbine can be

varied using a nozzle. This is an expensive method to achieve high efficiency.

Proven have manufactured their own variable nozzle at relatively low cost

to operate in these conditions. There are no set prices for any of the

hydro devices provided by Proven as all devices are POA (price on application).

The applications of solar in a small-scale environment are much the same as that of an urban environment so use the links below to see the Urban Solar Section.

Urban

Solar

Urban PV | Urban Passive

Biomass is an area that is ripe for the small-scale environment. Farmers or landowners can grow biomass fuel on their land and profit from it in one of two ways.

1. If there is a biomass

plant in close proximity to the land the 'biomass' can be sold to the

biomass station.

2. The individual can set-up a small-scale biomass station on their land.

There are advantages to both of these options. Both of these options would benefit from government support for set-aside land and growing biomass for power generation. Selling the 'biomass' to a large-scale plant benefits the landowner, as they do not have to put up much capital and benefit from growing an energy crop for profit. (Examples of operational large scale biomass power stations that use fuel including straw and poultry litter can be found in the Case Studies Section) The greatest benefit to the individual comes at the greatest cost. If a small- scale biomass plant is built and installed on the landowners property, they can generate their own electricity and reduce - or cancel - their heating bill altogether by setting up a CHP system.

Initialising a small-scale biomass plant for an individual or group of individuals will require a significant quantity of funding. Grants are available for this and The New Opportunities Fund (NOF) currently has £50 million available for renewable energy projects. On the website for the NOF (http://www.nof.org.uk) it states that there is at least £33 million to fund projects generating electricity from energy crops and at least £3 million for small-scale biomass heating schemes. On the website there is a form available to express interest in receiving funding from this source. (http://www2.dti.gov.uk/renew/bioenergygrant.pdf)

Another option available to the small-scale user is to purchase a commercially available small-scale biomass generator.

Farm 2000 boilers can produce

heat outputs ranging from 20-300 kW. They have been developed to produce

low cost heat by the controlled combustion of biomass, i.e. wood, woodchips,

straw, and waste material including cardboard packaging. By using waste

as energy, landfill volumes can be reduced. These boilers can operate

on both domestic and commercial levels controlling hot water, central

heating and warm air systems. Biomass is CO2 neutral because the crop

absorbs almost the same amount of carbon during its growth as it emits

during combustion. Therefore if a farm 2000 boiler replaces a fossil fuel

fired boiler, CO2 emissions can be reduced.

The farm 2000 boilers are shown above and increase from the small economy boiler to the largest boiler. From information provided by the manufacturer when a small dry bale (16% moisture content) weighing 16kg or approximately 14kg of wood is burned in a Farm 2000 boiler it will provide approximately 40kWh of heat. The same quantity of heat is provided from approximately 5 litres of oil. The website gives details on selecting the correct boiler for your specific heating load.

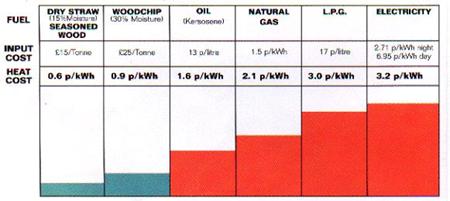

Below is a chart showing the costing of providing heat by different using different forms of fuel. The company claim that using dry straw is the most cost effective by providing heat at 0.6p/kWh compared to heat at 3.2p/kWh.

A typical use for this sort of biomass heat generation source is shown

in the schematic below. The boiler shown is providing heating for many

applications including grain drying and a swimming pool.

More information about these specific boilers can be found from the website - http://www.farm2000.com.uk

Farm heating provided by the combustion of large square bales of linseed straw.

A farmer purchased 73 ha (180 acres) of arable farm and decided to install a straw-burning boiler to provide heating and hot water for the large farmhouse. He had been made aware of the economics and reliability of straw boilers from his last farm. The boiler, supplied and installed by Teisen Products Limited, produces 75 kW of thermal energy and uses around 240 large, high-density square bales/year of linseed straw. The system requires one bale a day from October to March, and one bale every three days between April and September. The use of linseed straw means that only a small amount of ash is produced.

The boiler, chimney and accumulator cost £8,500 and installation of a central heating system, heat exchangers, pumps, valves, pipe work, electrical work and building alterations cost £11,000. Operating costs include £330/year for baling, 1 kWh/day of electricity for the fan and £100/year for maintenance. Labour is required to load bales into the boiler (15 minutes/bale) and for cleaning and ash removal (1 hour/month). (Each bale measures 84 cm x 84 cm x 210 cm and weighs around 205 kg.) Savings amount to £2,000/year in oil and electricity costs and there are savings in the cost of chopping and ploughing-in of surplus straw.

Combustion of Rape and Linseed Straw Bales Provides Heating for a Business Centre

20 small office units were

created as part of a refurbishment to Victorian farm buildings - total

floor area of around 1,500 m². As part of the refurbishment, the

owner installed a straw-fired boiler to provide heating and hot water

for sale to the units and for the 6-bedroom farmhouse and to provide background

heating for the farm workshop.

Teisen Products Limited supplied the boiler, which provides 200 kW of

heat energy 12 hours/day. The system burns 500 big bales of rape and linseed

straw a year. The straw is baled and transported to storage. Bales are

loaded into the boiler, two at a time, by forklift truck. Office and domestic

wastes are also used to supplement the straw supply.

The use of office and domestic wastes to supplement the straw supply provides a constructive disposal of these wastes. The total capital cost was £12,000. Installation was part of the overall refurbishment project and these costs are excluded. Operating costs include £5/bale for baling and handling straw, one hour each week for cleaning and ash removal, £100/year for electricity to drive the boiler fan, £1,500/year for maintenance and depreciation and 15 minutes each day for labour for loading bales into the boiler.

Heat sales to the office units provide an income of around £12,000/year and energy bills for the farmhouse and farm workshop are reduced.

The Resource - 28 million tonnes of waste are produced in the UK every year; of this currently only 9% recycled - 2.5million tonnes. That's a massive half a tonne per person - ½ tonne = 500kg per person

In a typical dustbin - 50% of the waste should be recyclable through re-use, composting, recycling Our household waste is made up of a number of different materials.

Utilisation

A lot of waste we produce

is disposed of in landfill sites. When this waste decomposes over time,

a lot of methane is given off. If left to accumulate in the atmosphere,

this methane can contribute to global warming. However, it can be utilized

to generate electricity by burning it. Although this releases carbon dioxide

into the air, it is not as strong a greenhouse gas as methane.

It has been estimated that 6 to 8 tones per cubic metre of methane gas

are produced from landfill gas extraction each year. This method was first

utilized to power boilers and furnaces in close proximity to the landfill

sites. However, present schemes use the gas to power engines and generate

electricity. Landfill gas currently provides approximately 100 megawatts

(MW or million watts) of electricity in the UK, with this figure set to

increase rapidly in the coming years.

Energy can be derived from waste besides the burning of methane. Firstly, when waste is incinerated in large amounts, heat energy can be recovered and used for heating schemes in factories, hospitals and other large-scale complexes. Secondly, waste-derived fuel can be burnt in many conventional boilers and larger combustion units. Unfortunately the fuel is not as energy-rich as coal, and is therefore not always economically viable for companies to utilise. Incentives are often required to encourage firms to use this type of fuel.

Energy from waste could be setup on a small scale if a group of the public joins forces to create a co-generation project. By setting up a small EFW plant the waste from a number of homes could be burned to produce heat for the homes.

Above has explained the technologies available for exploitation in a small-scale application. These can all be deployed individually to varying levels of power generation. The problem with utilising any renewable technology is that you are at the mercy of Mother Nature. The wind may stop blowing, the water may stop flowing, and the weather may not encourage healthy crop growth. If any of these things happen it could drastically reduce the ability to generate power. The best choice of renewable generation is to use diversification. By utilising more than one of the technologies the effect on the total generation will not be as greatly dependant on one source. If the wind stops blowing and there is also a water generation device power can be provided from that and the same applies if a biomass device is implemented. By using diversification the individual will become more self-sufficient and depend less on power coming from the national grid.

A suitably sited location could provide all heating requirements from the installation of a biomass generation device mentioned above and then generate all or a large proportion of the electrical requirements from the installation of a joint wind/water generation station.

The image shows a layout that may be implemented with 2 wind turbines installed and an Economy Farm 2000 burner to provide heating.

The above shows costs provided from the websites of the manufacturers

but does not include delivery and installation. Farm 2000 recommend using

specific chimneys and quote prices on application. Using the system above

the expected outputs from the system per annum will be estimated.

Electrical

2.5kW turbines * 2 = 5kW (rated wind speed 12m/s)

Assume a capacity factor of only 25% for these small wind turbines as

they are rated at 12m/s (rather than the more common 10m/s) and the availability

will be less than the large-scale turbines as the wind speed increases

with height.

Annual electrical output

= 5*8760*.25

= 10950kWh/annum

Thermal

The Farm 2000 boilers can be used for heating purposes and will provide

water heating.

Straw Fired: 16kW*8760 = 140160kWh/year (enough for nearly ten houses)

Wood Fired: 35kW*8760 = 306600kWh/year

The values shown above are for maximum output throughout the duration of the year. Obviously the burner will not be constantly used for all the 8760 hours in the year. Time will be required for loading and restocking of the fuel, maintenance and there are times when the user will not require large quantities of heat - nighttime and summertime.

The cost of the burner appears to be low compared to that of the wind turbines but the burner requires a lot more user interface than the turbine. Once a turbine is installed it can be left unattended to generate, with the exception of regular maintenance checks. The burner though requires a supply of straw/wood throughout the year and the user has to load the fuel into the burner. This is on top of the regular maintenance checks required like the wind turbines. The cost of running the burner increases, as a supply of fuel is required. From the information above it was mentioned that a small bale would produce approximately 40kWh. Therefore to produce the maximum output figures as stated above would require 140160/40 = 3504 bales of straw. If we take the price of a bale of straw as £0.25/small bale that is a fuel cost of £876/annum.

From information from Scottish and Southern the average kWh use of gas in a gas heated home is 19070 kWh. This will not all be used for heating (cooking) so the value for heating will drop to an estimated 16000kWh/year. To produce this quantity of electricity from a Farm 2000 boiler would require 16000/40 = 400 small bales of straw = £100/annum.

These values have been calculated

to try to give estimation on the effectiveness of the installation and

should not be taken as expected outputs. The manufacturers should be contacted

to get more information about installations.

![]()

Home, Beginners Guides, Large Scale, Urban wind, Policy, Links

![]()