Moorings

The station keeping system is not one the main cost figures involved in a wave energy project, as it only represents around a 5-10 % of the capital cost. However, there is great scope for its cost reduction.

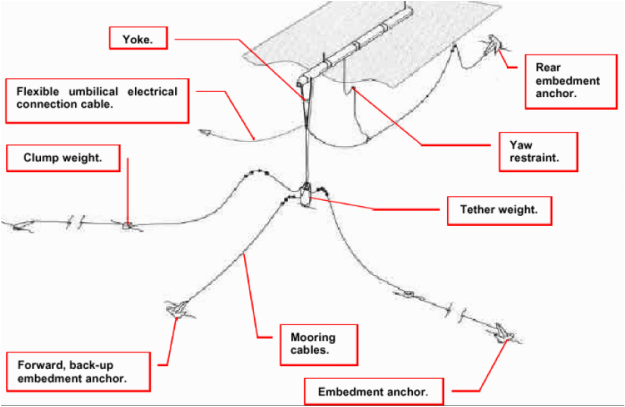

The mooring for floating structures usually consists in a group of cables and anchors that hold the device on station and prevent it drifting. The water depth, the tidal current and the tidal range are the main parameters that affect the design and cost of the mooring systems. Moreover, their design highly depends on the mean and extreme loads placed in them by the sea. Therefore, one of the main solutions is finding a way to reduce the loads on the mooring lines.

The mooring for floating structures usually consists in a group of cables and anchors that hold the device on station and prevent it drifting. The water depth, the tidal current and the tidal range are the main parameters that affect the design and cost of the mooring systems. Moreover, their design highly depends on the mean and extreme loads placed in them by the sea. Therefore, one of the main solutions is finding a way to reduce the loads on the mooring lines.

Moving to deeper waters, from 75m to 100m depth, can reduce the mooring cost significantly, because the extreme loads on the mooring system are significantly reduced. This is due to two important factors:

Another possibility for reducing the station keeping system’s cost is using other materials. Most of the mooring systems for floating devices consist of heavy metal cables, usually steel cables, accompanied by expensive anchors. Swiping to lighter mooring lines allows reducing the loads on the device. Nylon ropes have been regarded as a good alternative material for metal cables, as it is more compliant than steel, and can lead to lower loads on the machine. Moreover, nylon has shown to have good fatigue resistance, and although it is still necessary to research its fatigue performance in the wave environment, it is likely to last longer than steel and requiring less maintenance. Another advantage is that as nylon ropes are lighter, they are easier to handle during installation, lowering installation costs.

Regarding the anchor system, gravity bags made of fabric and filled with some aggregate can substitute other kind of expensier mooring systems such as gravity anchors, drag anchors or embedment anchors.

- The orbital motion of wave particles is essentially circular because the sea bed does not disturb the motion of the particles, reducing the extreme wave surge motions on the device, and thus the mooring loads.

- The length of the moorings is increased allowing a greater level of compliance of the device and reducing the extreme loads on the mooring and anchoring components. Therefore, the increase in water depth will be mostly accommodated by the less expensive tethers rather than lengths of chain.

Another possibility for reducing the station keeping system’s cost is using other materials. Most of the mooring systems for floating devices consist of heavy metal cables, usually steel cables, accompanied by expensive anchors. Swiping to lighter mooring lines allows reducing the loads on the device. Nylon ropes have been regarded as a good alternative material for metal cables, as it is more compliant than steel, and can lead to lower loads on the machine. Moreover, nylon has shown to have good fatigue resistance, and although it is still necessary to research its fatigue performance in the wave environment, it is likely to last longer than steel and requiring less maintenance. Another advantage is that as nylon ropes are lighter, they are easier to handle during installation, lowering installation costs.

Regarding the anchor system, gravity bags made of fabric and filled with some aggregate can substitute other kind of expensier mooring systems such as gravity anchors, drag anchors or embedment anchors.