|

Indoor

air quality is one of the most important aspects of occupant comfort in site

accommodation for construction villages. In order to provide a safe, healthy and

comfortable indoor environment, minimum ventilation standard need to be provided

depending on the pattern of occupancy and functionality of the accommodation.

Ventilation is required for one or more of the following purposes:

-

provision of fresh air for breathing

-

dilution and removal of airborne pollutants including

odours

-

control of excess humidity (arising from water vapour in

the indoor air)

-

provision of air for fuel burning appliances

-

provides a mean to control thermal comfort.

Ventilation system

is needed in an enclosed building to satisfy health, comfort and cooling needs.

It will be best provided with a good degree of local control. According to the

CIBSE Building Guide, the minimum required fresh air is 5 l/s per person (or 0.5

l/(s m2) while the recommended rate is 8 l/s per person (or 0.8 l/(s

m2). Unsatisfactory internal air quality in a cabin will happen with

too little fresh air. However, with too much ventilation, unnecessary heat

losses will occur with a waste of energy.

An enclosed space

can be provided with natural or mechanical ventilation, depending on the

condition and the environment. Natural ventilation which uses the pressure

differential of the air can be provided with very low capital and operating

costs. It has no mechanical or running parts therefore less maintenance as well

as noise pollution. However, external environment conditions may limit or

prevent the use of natural ventilation. For example, a high level of noise or

pollutants especially in a construction site.

This will then

require the use of mechanical ventilation system. It requires smaller openings,

provides controllability and security as compared with natural ventilation. The

disadvantage of mechanical ventilation is that it consumes electricity and cools

the air. Therefore, mechanical ventilation should be kept to a minimum of the

acceptable levels of indoor air quality.

Providing more

ventilation than is really required increases costs. This is because internal

‘conditioned’ (heated or cooled) air that is removed from a building has to be

replaced with the same amount of air from outside. This also needs to be heated

or cooled to match the temperature of the building. Besides, moving air around

mechanically, using fans uses electricity. Therefore, it is important to

determine the actual requirements and to design a ventilation system that suits

the specific functionality of the accommodations in construction villages.

Back to

Top

The objective of

this part of the project is to propose a methodology to identify the minimum

requirements and standards for ventilation for different types of cabin

accommodation to improve the indoor air quality and the comfort level for the

occupants. In addition to that, further analysis is conducted to recommend low

energy solutions for each accommodation type.

Back to

Top

|

|

The

methodology of this study is divided into two parts

-

To evaluate the required ventilation rate that satisfy the

minimum standards for each type of accommodations

-

To select the best possible ventilation system and control

solutions based on identified requirements, energy demand and costs

|

i)

Evaluation of the required ventilation rate

In order to

determine the level of ventilation required, it is important to identify the

conditions of the surrounding, the kind of activity being carried out and the

level of occupancy in the cabin accommodation. There are five factors that will

influence the design of the ventilation system requirement in a cabin

accommodation as shown in the figure above. The five factors described in detail are:

1)

External Air Quality

The external

environment is an important factor to be considered when designing a ventilation

system. Noise level, ambient air temperature and pollution from dust and smoke

will determine if natural ventilation would be possible.

2)

Occupancy Levels

Occupancy levels

will determine the amount of air change that is required for a cabin

accommodation depending on the standard minimum requirements to satisfy health,

comfort and cooling needs of occupants. According to the CIBSE Building Guide,

the minimum required fresh air is 5 l/s per person (or 0.5 l/(s m2)

while the recommended rate is 8 l/s per person (or 0.8 l/(s m2).

3)

Occupancy Activity

The type of

activity people does in the cabin accommodation will also determine the required

air change rates and the ventilation system required. People moving around

require more air than those who are stationary.

4)

Relative Humidity Level

Some specific

accommodation such as the drying room in construction villages need ventilation

to control the humidity level and for creating air flow to dry clothes.

5)

Indoor Pollutants

The types of

equipments and materials used indoor will also emit pollutants such as from

synthetic carpets, photocopying machines, fresh paints, etc. which will need a

higher fresh air to remove those pollutants that poses health threat to

workers.

ii)

Selection of best options of ventilation system and control solutions

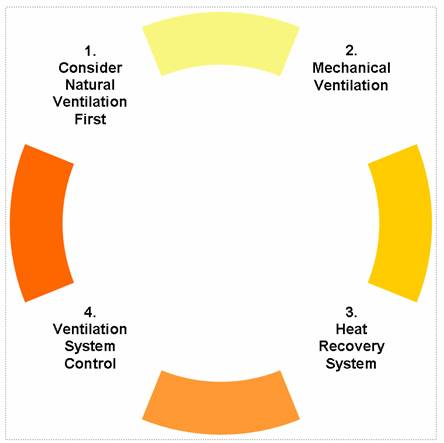

Low energy design

shall be considered when designing the ventilation system to the requirements

determined from the first part of the methodology. By designing the system as

close to the required air change rate as possible will prevent excess of

ventilation which will cause wastage of energy. The following are the design

strategies that can be used when designing ventilation system for cabin

accommodations.

|

1)

Consider natural ventilation first

Natural ventilation does not require any mechanical components or

power and therefore require little or no energy at all. It depends

on the pressure differential of the external and internal

environment to provide the natural air change. However, poor

external air quality and heat losses could cause discomfort and the

increase in heating load.

2)

Mechanical ventilation

Mechanical ventilation can be provided by a fan system at

varying air change rate depending on requirements. The fan can be

chosen according to the air change requirements calculated for the

specified area, occupancy level and occupancy activity.

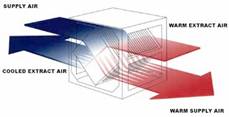

3) Mechanical ventilation with heat recovery

In

addition to the ventilation fan, it is possible to have a heat

recovery system that can reduce the cost of conditioning or heating

the incoming air by recovering some energy from warm or cool exhaust

air. This system will cost more but the efficiency in heat recovery

would give less heat losses and reduce the heating demand.

4)

Ventilation system controls

Energy

savings can be enhanced further by matching flow rates to demand and

introducing control to the operating times. Ventilation rates may

not need to be constant throughout the day, especially if building

occupation varies during operating hours. Variable-speed fans

controlled by levels of CO2 or process pollutants can be

used. As the need for ventilation increases, fan speeds increase and

more air is brought in. Below are some different control strategies

that could be used for different purpose.

a.

Control with on/off occupancy sensor

Ventilation control using occupancy sensor will operate when the

sensor detects occupancy and will reduce the ventilation rates

during periods of non-occupancy or low level of process activity.

Sensors can monitor and control ventilation rates, meeting occupant

safety and process requirements and minimizing energy consumption.

This system could best used in places such as toilets and store

rooms in construction villages where there are only occasionally

occupied and for a short duration.

|

|

b.

Control with Carbon Dioxide sensor

The

levels of CO2 are monitored and ventilation rates

increase as CO2 levels rise. The level of CO2

is a good indicator of the per-person ventilation rate, since its

presence depends on the number of people in a space and the rate at

which the air in the space is being diluted with outdoor air. This

system controls the outside air volume by regulating CO2

levels. When the CO2 level in the area reaches a

predetermined level, an electronic controller adjusts the

ventilation rates accordingly. This type of system is more precise

than occupancy sensors, as it can adjust for different rates of

occupancy demand, based on levels of physical activity, age and

health. Ventilation control based on CO2 levels is an

important tool that can help control occupant-related pollutants and

satisfy occupant-based ventilation standards. This control type is

very effective in meeting rooms and canteen of construction villages

with varying occupancy pattern all the time. The most common

application measurement of indoor air for CO2 concentration is

typically less than 1,000 PPM in properly ventilated buildings.

Note: Air

Composition

Fresh air contains 21% oxygen and 0.03% carbon dioxide.

Expired air is typically 16% oxygen and 4% carbon dioxide.

CO2 levels > 5% (50000 ppm), acute danger to health (also if

O2 < 12%)

CO2 levels > 0.35% (3500 ppm), long term health implications

CO2 levels > 0.1% (1000 ppm), poor comfort

c.

Control with humidity sensor

Humidity control

increase ventilation rates when internal humidity levels rise. The system uses a

humidistat that can be set to the required humidity level to be maintained as

required. This control is effective in the drying room of construction villages

by maintaining the required humidity level so as to prevent air saturation which

deters clothes from drying.

Back to

Top

This case study is

conducted to determine the minimum ventilation requirement of a standard cabin

accommodation design that serves different functions based on the building

standards mentioned in the introduction. Knowing the requirements, ventilation

systems and control options are proposed for the different cabin functions.

i)

Evaluation of ventilation rate requirements

Assumptions

-

A typical standard cabin with a size of 9.5m x 3.0m x

2.5m high is used for analysis.

-

The minimum required fresh air is 5 litres per second

per person while the recommended rate is 8 litres per second per person.

-

The external air quality depends on the location of the

accommodation in the construction site and the amount of noise and pollution

level at site. In typical construction sites, pollution from dust, airborne

particles and noise are common. Therefore, it is common to minimize the use

of uncontrolled natural ventilation for site accommodations.

|

|

|

Accommodation

|

Ventilation Rate Requirements |

|

Cabin

Offices

|

There will

be 2 offices in a cabin which can house 2 workers each. So there will be

4 workers whose activities are quite stationary doing desk job and

assuming the offices are occupied 80% of the time. The minimum required

fresh air rate will then be 20 l/s for the whole cabin during office

hours which translates to about 1 air change per hour (AC/hr). The

recommended air change rate will be 1.6 AC/hr.

|

|

Meeting

Room

|

A meeting

room of this size can accommodate up to about 10 people at any one time.

The number of people and duration of use will vary a lot in this room

and it is assumed that it will be occupied 40% of the time during office

hours. The minimum fresh air rate will be 2.5 AC/hr with a recommended

4.0 AC/hr for 10 people.

|

|

Toilets

and Washing Area

|

This area

will normally be inhabited but will need fresh air to remove odours at

very intermittent intervals. The occupancy rate is assumed to be 20% of

the total working hours. The minimum fresh air rate is recommended to be

about 2 to 4 AC/hr.

|

|

Canteen

|

The

canteen area where workers have their meals and rest need to be well

ventilated. One cabin of this size can fit about 24 workers when fully

occupied during tea and lunch time. At other times, there will be

cleaners and some guests around. It is assumed that the canteen will be

occupied 30% of the working time. The minimum fresh air rate for the

maximum number of occupants will be about 6 AC/hr with a recommended

rate of 10 AC/hr.

|

|

Canteen

Kitchen

|

The

kitchen area in average will have about 5 workers doing some cooking and

food preparation during the canteen operating hours from 8.00am to

4.00pm. Heavy cooking requires a more intense ventilation to prevent

moisture build-up and dispersing of smoke. Due to the intense activity

requirement, a minimum ventilation rate of about 20 AC/hr is required

with 40 AC/hr recommended.

|

|

Drying

Room

|

Ventilation in the drying room is needed for the purpose of controlling

the excess humidity to avoid saturation when the water evaporates from

the wet clothing and to make sure clothes dry within the specified time.

In order for the clothing to dry between 1700 and 0730 the next day, the

temperature and relative humidity of the room is to be maintained at

20ºC and 30% respectively with an air extraction rate of 157 m3/hour

or 2.2 AC/hr |

|

|

|

|

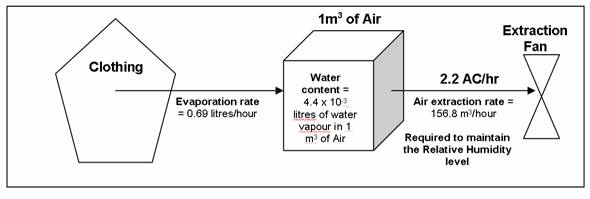

Determining the

Ventilation Requirements of Accommodation Types |

|

Drying Room

Ventilation Requirements

This study is

conducted to determine the minimum ventilation requirement for a standard drying

room.

Assumptions

i) Every working day, 0.25 litres of water on each set of clothes are

brought in to the drying room and there are 40 sets of clothes to be dried in

the drying room of standard size.

ii) The

clothes need to be dried overnight from 1700 to 0730 the next day.

Analysis

i) Total

amount of water to be evaporated = 0.25 litres x 40 sets = 10 litres

ii) Total

time required = 14.5 hours

iii) The

evaporation/dehumification rate required = 10/14.5 = 0.69 litres/hour

|

Increase in the

air temperature will cause increase of vapour pressure, increase moisture

content and therefore delayed the saturation of the air in the room. Warm air

can hold more moisture than cold air before reaching the saturation point. With

the air temperature in the drying room maintained at 20ºC, the relative humidity

can be maintained if the water vapour produced is removed from the air at the

rate equal to the evaporation rate of the water vapour from the clothing.

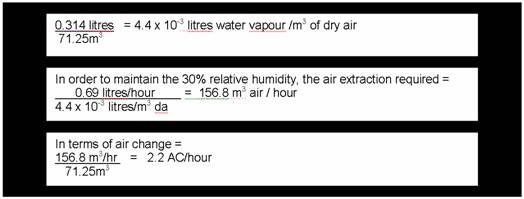

Assuming temperature of 20ºC and relative humidity of 30% is

maintained. From psychometric chart of moisture and temperature, the

water content of air is 0.0044 kg/kg of dry air. Taking the size of

the drying room to be the standard cabin size of 9.5m x 3.0m x 2.5m

high with a volume of 71.25m3, the water content of the

drying room air will be 0.314 litres.

|

|

|

Therefore, in order for the clothing to dry between 1700 and 0730

the next day, the temperature and relative humidity of the room is

to be maintained at 20ºC and 30% respectively with an air extraction

rate of 157 m3/hour or more.

|

ii)

Selection of Ventilation System and Control Options

The

selection methods are based on the methodology as described in the methodology

section.

|

|

Minimum Ventilation Requirements (Recommend)

AC/hr*

|

Flow rate required

m3/hr

|

Ventilation System and Control Options with Low Energy Design

|

Investment / Cost**

£ |

Average Estimated Energy Use per annum**

kWh/year |

|

Cabin Offices |

1.0

(1.6) |

71.25

(114) |

With the small requirement in offices (< 2 AC/hr), natural

ventilation can be used and the opening and closing of

windows and doors manually is sufficient to provide the

required fresh air rate.

|

Nil |

Nil |

|

Meeting Room |

2.5

(4.0) |

178.1

(285) |

Option 1: Natural ventilation can be used if the door is to

be left

open for meeting duration.

Option 2: If meetings are to be conducted with closed door

for more than 1 hour with 10 people or more, then

ventilation fan with flow rate of 180 to 285 m3/hr

with heat recovery is recommended.

- Ventilation system to be fitted with controls with

occupancy sensor

|

£ 290.06 (with 75% efficiency)

£ 30.45

|

130W x 40% x 11 hours x 5 x 52 =

148.7 kWh

|

|

Toilets |

2.0

(4.0)

|

142.5

(285) |

Ventilation fan with flow rate of 143 to 285 m3/hr

range is recommended.

- Ventilation system to be fitted with controls with on/off

occupancy sensor (Passive Infrared + Timer)

|

£ 50.00

£ 44.10 |

50W x 20% x 11 hours x 5 x 52 =

28.6 kWh

|

Canteen |

6.0

(10.0) |

427.5

(712.5) |

Ventilation fan with flow rate of 428 to 713 m3/hr

with heat recovery system is recommended. (Cost and energy

use is calculated based on fan with maximum flow rate of 550

m3/hr with 70% efficiency)

- Ventilation system to be fitted with controls with CO2

sensor

|

£ 553.33

£ 61.95 |

150W x 30% x 11 hours x 5 x 52 =

128.7 kWh |

|

Kitchen

|

20.0

(40.0)

|

1425

(2850) |

Ventilation fan with flow rate of 1425 to 2850 m3/hr

with variable speed is recommended.

(Cost and energy use is calculated based on fan with 1650 m3/hr

flow rate)

|

£ 350.00

|

90W x 8 hours x 5 x 52 =

187.2 kWh |

|

Drying Room |

2.2

|

156.8

|

Ventilation fan with flow rate of 156.8 m3/hr or

more with heat recovery is recommended. (Cost and energy use

is calculated based on fan with maximum flow rate of 220 m3/hr

with 75% efficiency)

- Ventilation system to be fitted with controls with

humidity sensor |

£ 290.06

£ 30.45

|

130W x 24hours x 5 x 52 =

811.2 kWh

|

|

|

|

|

|

|

|

|

*Calculated based on minimum required fresh air rate of 5

litres/second per occupant and (based on recommended 8 l/s

per occupant).

**The investment and averaged energy use per annum is

calculated based on information obtained through ventilation

system supplier’s website that best met the required

ventilation rate. |

|

Suppliers of

the recommended ventilation system and control options

|

|

Ventilation Systems and Control Options Recommended

|

Supplier and contacts

|

|

Cabin Offices |

Nil |

Nil

|

|

Meeting Room |

|

Intervent HRV200WK unit utilises energy efficient AC

external rotor motors. The counter flow heat exchanger

matrix also ensures that the maximum amount of heat is

recovered from the stale exhaust airflow and is utilised to

warm the supply air as it is brought into the building.

Control options include a simple 2-speed switch, Humidisense,

Timesense and Occusense. On average over 75% of heat is

transferred from the stale air to the incoming fresh air.

http://www.admsystems.co.uk |

|

Toilets |

|

Code: SDF 100PIR

Model : PIR & Timer

http://www.silavent.co.uk |

|

Canteen |

|

Intervent HRV-500

Control options include a simple 2-speed switch and

Occusense.

http://www.admsystems.co.uk |

|

Kitchen |

|

VARIO 300/12" ARI-LL-S

Axial Wall/Ceiling Recessed Reversible

[Long Life Motor]

[12in 1650m3/hr] [ABS White]

http://www.vortice.co.uk |

|

Drying Room |

|

Intervent HRV-200WK

Control options include a simple 2-speed switch and

Humidisense

http://www.admsystems.co.uk |

|

Back to

Top

Different

types of cabin accommodation requires different ventilation rate for the purpose

of satisfying the minimum safety and health requirements as well as providing

the sufficient level of comfort to the occupants in construction villages. The

ventilation requirements in a cabin accommodation at construction villages can

be evaluated using the methodology above and low energy ventilation systems

could be selected based on the requirements and functional considerations of

each accommodation type. Although providing ventilation to the accommodation

requires energy, the indoor air quality and comfort level could be enhanced and

indirectly will contribute to the increase in productivity and good health of

the workers in construction villages.

Back to

Top

- Kreith, Frank,

West, Ronald E., CRC Handbook of Energy Efficiency, CRC Press, 1997, pg 285 –

291

- McMullan,

Randall, Environmental Science in Building, Fifth Edition, 2002

- Office of the

Deputy Prime Minister, Document F - Ventilation, The Building Regulations

2000, pg 6.

-

The

Carbon Trust, Energy Saving Fact Sheet - Ventilation, May 2005.

-

http://www.admsystems.co.uk

-

http://www.dealec.co.uk

-

http://www.silavent.co.uk

-

http://www.vortice.co.uk

Back to

Top

|