Introduction to Combined Heat & Power

What is CHP ?

Combined Heat and Power (CHP) or Cogeneration is the simultaneous production of useful heat

and electricity in the same plant. Conventional electricity generation is via large power

stations releasing low-grade heat into the atmosphere as a wasted by-product. By retrieving

some of this rejected heat via heat exchangers and being situated near where it can be used,

CHP plants can greatly increase their overall efficiency and provide heat to commercial,

industrial or public sectors at the same time as producing electricity.

A Typical CHP System

| The main components of a typical system are:

- the engine or prime mover which drives the generator.

- the generator which produces electricity.

- the heat recovery system that recovers the waste heat from both the engine water cooling jacket and exhaust gases.

- the exhaust system to take away the products of combustion.

- the control panel to monitor the operation.

|

Types of CHP systems

There are five principal types of CHP system :

Back pressure steam turbine systems,

where steam at high pressure is generated in a boiler and is wholly or partly used in a turbine

being exhausted from the turbine at the required pressure for the site. A proportion of the

steam used by the turbine may also be extracted at an intermediate pressure from the turbine

(a pass-out/back pressure steam turbine).

Back pressure steam turbine systems,

where steam at high pressure is generated in a boiler and is wholly or partly used in a turbine

being exhausted from the turbine at the required pressure for the site. A proportion of the

steam used by the turbine may also be extracted at an intermediate pressure from the turbine

(a pass-out/back pressure steam turbine).

Pass-out condensing steam turbine

systems, where a proportion of the steam used by the turbine is extracted at an intermediate

pressure from the turbine with the remainder being fully condensed before it is exhausted at

the exit (pass-out/condensing steam turbine).

Pass-out condensing steam turbine

systems, where a proportion of the steam used by the turbine is extracted at an intermediate

pressure from the turbine with the remainder being fully condensed before it is exhausted at

the exit (pass-out/condensing steam turbine).

Gas turbine systems, where fuel is

combusted in the gas turbine and the exhaust gases are normally used in a waste heat boiler to

produce usable heat, though the exhaust gases may be used directly in some process applications.

Gas turbine systems, where fuel is

combusted in the gas turbine and the exhaust gases are normally used in a waste heat boiler to

produce usable heat, though the exhaust gases may be used directly in some process applications.

Reciprocating engine systems,

producing two grades of waste heat: high grade heat from the engine exhaust and low grade heat

from the engine cooling circuits. Two principal types of engine exist: compression ignition and

spark ignition, dependent on their firing method.

Reciprocating engine systems,

producing two grades of waste heat: high grade heat from the engine exhaust and low grade heat

from the engine cooling circuits. Two principal types of engine exist: compression ignition and

spark ignition, dependent on their firing method.

Combined cycle systems, where the

plant comprises one or more engines (usually gas turbines but in some cases reciprocating

engines) whose exhaust gases are utilised in a steam generator, the steam of which is used

wholly or in part in one or more steam turbines.

Combined cycle systems, where the

plant comprises one or more engines (usually gas turbines but in some cases reciprocating

engines) whose exhaust gases are utilised in a steam generator, the steam of which is used

wholly or in part in one or more steam turbines.

Back to Top

Typical characteristics of CHP systems(ref.1)

| Spark Ignitiion Engine | Compression

Ignition Engine | Gas Turbine | Combined Cycle | Back

Pressure Steam Turbine | Pass Out Steam Turbine |

| Fuel

Type | Natural gas, Biogas... | Natural gas, Biogas, Gas oil, Heavy oils |

Natural Gas, Biogas, Gas Oil | Natural Gas, Biogas, Gas Oil | All

types | All types |

| Capacity Range | 30 kWe to 2 MWe |

100 kWe to 20 MWe | >1 MWe | >3 MWe | >500 kWe | >1MWe |

| Heat:Power Ratio | 1:1 to 3:1 | 0.5:1 to 1.5:1 (3:1 with boost

firing) | 1.5:1 to 2.5:1 (5:1 with supplementary firing) | 1:1 (3:1 with

supplementary firing) | 3:1 to 10:1 | 3:1 to 8:1 |

| Heat Output

Quality | LPHW, Steam (rare) | LPHW, Steam | High Grade Steam |

Medium Grade Steam | Medium Grade Steam | Steam at 2 pressures |

| Electrical generating Efficiency % | 25-33 | 35-42 |

25-40 | 35-50 | 7-20 | 10-20 |

| Overall

Efficiency % | 70-78 | 65-75 (75-82 with boost firing) | 65-80 (75-82

with suppl. firing) | 73-80 (80-85 with suppl. firing) | 75-84 | 75-84 |

Emerging Technologies

The phrase cogeneration is normally applied to gas or oil burning generating plants, however

the following emerging technologies are by definition cogeneration :

CHP Hybrid

Photovoltaics - pv cells integrated in building designs such that the waste heat generated by

the module can be extracted and used for either space heating or hot water purposes(ref.2) CHP Hybrid

Photovoltaics - pv cells integrated in building designs such that the waste heat generated by

the module can be extracted and used for either space heating or hot water purposes(ref.2) |

Fuel Cells - electrochemical

reactions between hydrogen and oxygen producing heat and electricity simultaneously. For

further information link tohttp://www.fuelcells.org/ Fuel Cells - electrochemical

reactions between hydrogen and oxygen producing heat and electricity simultaneously. For

further information link tohttp://www.fuelcells.org/

|

Back to Top

Applications

Many people only consider the uses for heat and power as space heating and electrical

generation. While this may be the most opportune and economic pathway for most sites it should

not be forgotten that direct use of the outputs of your CHP unit might be better used

unconverted.

| A good example of direct use of CHP is on oil rigs where for example on the East Brae

platform three 34.5 MWe gas turbines are used purely for compressor duty with the heat being

used to liquefy the crude oil (ref.3). For the last century ocean liners have used CHP, but it

is only recently that the economics have begun to favour their use on land. |

Looking at the plant outputs in isolation the vast majority of shaft power is turned into

electricity using synchronous generators, although, along with wind turbines, there is a move

to variable speed operation in an attempt to maximise generation. This is normally achieved

using power electronics to modulate the output. Work is being carried out looking into the

use of shaft power to drive a heat pump directly for use in a domestic setting (ref.4) and

such use over the years has attracted a lot of attention.

Typical installations:

Hospitals & Air Ports, where there is already a

requirement for stand-by power.

Hospitals & Air Ports, where there is already a

requirement for stand-by power.

District Heating Systems.

District Heating Systems.

Manufacturing Complexes.

Manufacturing Complexes.

New Build & Retrofit Offices.

New Build & Retrofit Offices.

Horticulture.

Horticulture.

The heat and exhaust products can most obviously be used to raise steam and hot water for

process work or district heating. An example of such a plant is the 80 MWe setup at

Kemsley Mill, Kent, constructed by Kvaerner Energy of Clydebank, which raises 300 tonnes

of steam per hour for use in paper processing. Of course exhaust products can be used more

directly by venting it directly into nursery greenhouses providing the growing plants with

a supply of high grade, warm, CO2 (ref.5). For those of us working in building services

perhaps the fastest moving development is the implementation of absorption coolers. The

BBC’s Television Centre in West London has a EGT 4.9 MWe gas turbine supplying baseload

electricity coupled to absorption chillers with a capacity

of 6 MW (1,710 tonnes/hr to 7 C)(ref.6).

Back to Top

Benefits

Economic/Management

Depending on the site and the correct choice of plant, savings made on electricity should

more than offset the increase in fossil fuel (usually gas) requirements. This is especially

true in the recent market where electricity prices/unit are considerably more than gas

prices/unit. In some cases further savings from reduced maximum demand charges can also be

made. For suitable small/medium scale CHP sites, energy bills can be reduced by as much as

40 % with typical paybacks of down to 3 or 4 years.

Having an independent supply of electricity avoids relying on the fluctuating price of

supplied electricity, and also increases security of power supply, as the CHP unit can continue

to supply power should the grid fail, and vice versa.

The Environment

In conventional generation, 30-50% of the energy consumed is converted to electricity, the

remainder being rejected to the environment as heat, mainly through cooling towers or

condensers. About 8% of this electricity (i.e. a further 3% of energy input) is lost during

transmission and distribution to the end-user. The fuel efficiency of industrial CHP plant

can be around 80% or more and, as the plant is situated on-site, the losses from transmission

and distribution are minimal. For a given combination of industrial electricity and heat

demands using CHP, 10-40% less fuel is required than with conventional systems.(ref.7)

| The increased fuel efficiency of CHP gives it a potentially

useful role in helping to combat global warming, through curbing the emission of carbon

dioxide (CO2), the principal man-made greenhouse gas. This table shows

how this effect depends on the fuel being displaced by CHP. | Impact of Gas-Fired

CHP on CO2 Emissions (ref.8)

| Displaced power station fuel | Coal | Coal | Gas | Gas |

| Displaced Boiler Fuel | Coal | Gas | Coal | Gas |

| CO2 emission reduction (tC/MWe/year) | 2833 | 1622 | 1486 |

315 | | Percentage CO2 reduction | 57 | 44 |

41 | 13 |

|

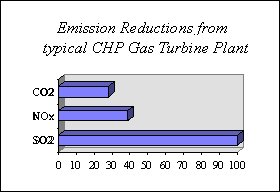

| Increased fuel utilisation efficiency and reduced emissions from CHP plant can also

help to reduce acid rain by cutting emissions of sulphur dioxide (SO2)

and nitrogen oxides (Nox). The graph(ref.9) shows emissions compared with

a gas-fired boiler and average 1993 UK plant mix.

NOx emissions can actually be increased from small scale gas engine CHP, but this can be

avoided by the use of a catalytic converter.

|

CHP has the added benefit that it can be employed in tandem with use of non-fossil

fuels also, such as LFG, biomass or even MSW incineration.

Back to Top

References

1. Guide 60, Best Practise Programme Publications, Energy Efficiency Office, Department of the Environment.

2. 13th,14th European Photovoltaic Solar Energy Conference.

3. "Why burn Champagne?", K.A. Bray, GEC Review,Vol.12, No.3, 1997

4. SMITH M.A, TWIDELL J.W. and FEW P.C., "Operational, Economic and Environmental Performance

of a Small Scale Combined Heat and Power Plant.", EMAGE Conference, Nottingham

Trent University, June 1995.

SMITH M.A, "Technical and Operational Performance of Small-Scale "In-House"

Combined Heat and Power.", East Midlands Renewable Energy Group Conference, Loughborough

University, June 1995.

5. Van Heyningen Brothers Nursery, ETSU Fact sheet.

6. Energy Management, January/February 1997, Department of the Environment.

7,9. The Electricity Association Homepages. At http://www.electricity.org.uk/

8. Assumptions:

- Heat/power ratio 3:1

- Load factor 90%

- CHP efficiency 81 %

- Displaced boiler efficiency 80% (coal), 86% (gas)

- Displaced public electricity supply generation efficiency 34%(coal), 50% (gas)

- Electricity transmission/distribution loss 8%

Source: SPRU evidence to the House of Lords Select Committee on the European Communities:Carbon/EnergyTax (HL Paper 52, March '92).