Current

situation:

The following assumptions have been made.

Heating

behaviour of occupants:

Lighting

behaviour of occupants:

The results

shown in the tables below have been arrived from a combination

of ESP-r simulations and calculations.

|

|

Annual energy demand

|

Lighting

|

226.5

kWh |

|

Heating |

1235

kWh |

|

|

For

a typical winter day (7:00 – 18:00) |

Thermal percentage

dissatisfied

|

40.53 %

(16.51% standard variation) |

|

Thermal comfort 1 |

1 h

(mainly overheated) |

1

Hours

per day where the dry resultant temperature lies between 20°C

and 22°C

Proposed

Situation:

Following energy efficiency measures have been applied

The

following assumptions have been made:

Heating:

Lighting:

-

25 % less

lamp rating (HF control)

-

65 % annual

savings through day light control (hardly surrounding

buildings; clean windows, little use of blinds)

The results

shown in the tables below have been arrived from a combination

of ESP-r simulations and calculations.

|

|

Annual energy demand

|

Lighting

|

59.5

kWh |

|

Heating |

471 kWh

|

|

|

For

a typical winter day (7:00 – 18:00) |

Thermal percentage

dissatisfied

|

8.25 %

(10.05% standard variation) |

|

Thermal comfort 1 |

10 h

(mainly overheated) |

1

Hours

per day where the dry resultant temperature lies between 20°C

and 22°C

Back to Top

The canteen

consists of 5 cabins and has the following characteristics:

-

Occupied by

workers from 10:00 to 11:00 and 13:00 to 15:00

-

Occupied by

cleaner from 11:00 to 12:00

-

4 x 2kW

heaters and 25 x 36W lights

-

Infiltration: 2ac/h during tea and lunch time, otherwise

1ac/h

Current

situation:

The following assumptions have been made.

·

Heating behaviour of occupants:

Lighting

behaviour of occupants:

The results

shown in the tables below have been arrived from a combination

of ESP-r simulations and calculations.

|

|

Annual energy demand

|

Lighting

|

2831.4

kWh |

|

Heating |

4680

kWh |

|

|

For

a typical winter day (8:00 – 16:00) |

Thermal percentage

dissatisfied

|

52.63 %

(19.77% standard variation) |

|

Thermal comfort 1 |

0.5 h

(mainly overheated) |

1

Hours

per day where the dry resultant temperature lies between 20°C

and 22°C

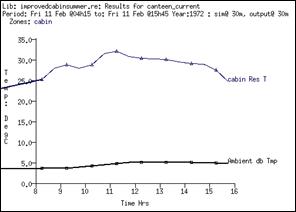

The picture

below demonstrates the dry resultant temperature inside the

canteen on a typical winter day. The upper line shows the dry

resultant temperature, the lower line shows the ambient

temperature.

Ambient and canteen’s dry resultant temperature

There is a

discomfort inside the canteen due to overheating and poor air

quality.

Proposed

Situation:

Following energy efficiency measures have been applied.

-

High

frequency ballasts

-

Occupancy

sensor for lights

-

1.5kW

heater with automatic temperature control (set from 8:00 to

15:00)

-

5

ventilators with 550m3/hr with heat recovery and

CO2 sensor (rated 150W)

The

following assumptions have been made:

Heating:

Lighting:

Ventilation:

The results

shown in the tables below have been arrived from a combination

of ESP-r simulations and calculations.

|

|

Annual energy demand

|

Lighting

|

764.5

kWh |

|

Heating |

3550

kWh |

|

Ventilation |

780 kWh |

|

|

For

a typical winter day (8:00 – 16:00) |

Thermal percentage

dissatisfied

|

13.78 %

(17.95% standard variation) |

|

Thermal comfort 1 |

4 h

(mainly overheated) |

1

Hours

per day where the dry resultant temperature lies between 20°C

and 22°C

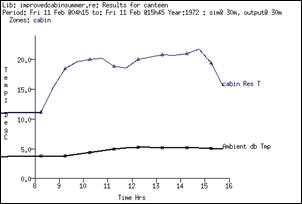

As stated in the table, the dry resultant temperature cannot

be maintained over the whole day.

However, a

comfort temperature of 20°C dry resultant temperature is

maintained during tea and lunchtime as shown in the graph below.

The upper line shows the dry resultant temperature, the lower

line shows the ambient temperature.

Ambient and

canteen’s dry resultant temperature

Back to Top

The drying room

consists of 2 and a half cabins and has the following characteristics:

-

Intermittent occupied (mainly at tea and lunchtime and

before work end)

-

2 x 2kW and

8 x 150W heaters

-

9 x 36W

lamps

-

Infiltration: 1.5 ac/hr during working hours

Current

situation:

The following assumptions have been made

·

Heating behaviour of occupants:

-

0:00

–24:00: 2kW heaters on medium power (2 x 1200W)

-

0:00

–24:00: 150W heaters on full power (8 x 150W)

Lighting

behaviour of occupants:

The results

shown in the tables below have been arrived from a combination

of ESP-r simulations and calculations.

|

|

Annual energy demand

|

Lighting

|

1019.3

kWh |

|

Heating |

22464

kWh |

|

|

For

a typical winter day (7:00 – 18:00) |

Thermal percentage

dissatisfied

|

88.37%

(24.3% standard variation) |

|

Thermal comfort 1 |

0 h

(always overheated) |

1

Hours

per day where the dry resultant temperature lies between 20°C

and 22°C

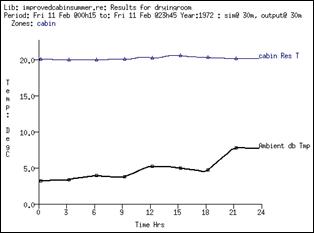

The picture

below demonstrates the dry resultant temperature and ambient

temperature inside the drying room for a typical winter working

day. The upper line shows the dry resultant temperature, the

lower line shows the ambient temperature

Ambient and cabin’s dry resultant temperature

It is shown

that a dry resultant temperature about 40°C is maintained 24

hours during working days without ventilation. It is obvious

that there is wastage of energy in addition to the problem that

the clothes do not dry overnight.

Proposed

Situation:

Following energy efficiency measures have been applied.

·

-

High frequency ballasts

-

Occupancy sensor for lights

-

5 x 1.5 kW heater with automatic control to replace all existing heaters

-

3 Ventilators with 220m3/hr with heat recovery and humidity sensor (rated 130W)

The following

assumptions have been made:

·

Heating:

-

Heating

control to maintain 20°C dry bulb temperature (24h per day)

·

Lighting:

-

25 % less

rating (HF ballast)

-

Lights

switched on for 20% of working hours

·

Ventilation:

-

Switched

on 24h per working day

-

3 AC/hr per cabin with 75% heat recovery

The results

shown in the tables below have been arrived from a combination

of ESP-r simulations and calculations.

|

|

Annual energy demand

|

Lighting

|

152.9

kWh |

|

Heating |

7,567.6

kWh |

|

Ventilation |

2,433.6

kWh |

|

|

For

a typical winter day (7:00 – 18:00) |

Thermal percentage

dissatisfied |

6.03%

(0.43% standard variation) |

|

Thermal comfort

1 |

10.5 h

(always overheated) |

1

Hours

per day where the dry resultant temperature lies between 20°C

and 22°C

The picture

below demonstrates the dry resultant temperature and ambient

temperature inside the drying room for a typical winter working

day. The upper line shows the dry resultant temperature, the

lower line shows the ambient temperature

Ambient and cabin’s dry resultant temperature

It is shown

that a dry resultant temperature about 20°C is maintained 24

hours during working days. Thus, the drying room of improved

standard provides an effective environment for clothes drying.

Back to Top

The

subcontractor’s cabin is a 9.5m x 3m cabin with the following

characteristics:

-

3 occupants

for 5 hours per day

-

1 computer

(7:00 –18:00)

-

2 x 2kW

heater and 5 x 58W lamps

-

Infiltration: 4ac/h (doors open)

Current

situation:

The following assumptions have been made.

· Heating behaviour of occupants:

-

7:00 - 9:00

both heaters on maximum power (2 x 2000W)

-

9:00 -

18:00 both heaters on middle power (2 x 1250W)

Lighting

behaviour of occupants:

The results

shown in the tables below have been arrived from a combination

of ESP-r simulations and calculations.

|

|

Annual energy demand

|

Lighting

|

912 kWh |

|

Heating |

3965

kWh |

|

|

For

a typical winter day (7:00 – 18:00) |

Thermal percentage

dissatisfied |

24.34%

(30.58% standard variation) |

|

Thermal comfort

1 |

2 h

|

1

Hours

per day where the dry resultant temperature lies between 20°C

and 22°C

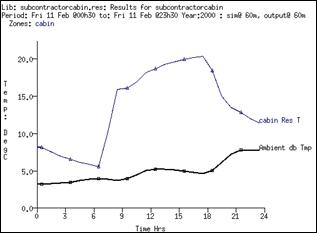

Pictures below

demonstrate the dry resultant temperature inside the

subcontractor’s cabin for a typical winter day. The upper line

shows the dry resultant temperature, the lower line shows the

ambient temperature

Ambient and

cabin’s dry resultant temperature

It is

demonstrated that the required dry resultant temperature of 20°C

cannot be maintained. During a typical winter day the dry

resultant temperature inside the subcontractor’s cabin will

typically be below the required comfort level. Thus, discomfort

will be experienced.

Proposed

Situation:

Following energy efficiency measures have been applied.

·

Improve insulation

-

36W T5

tubular fluorescent lights

-

Occupancy

sensor for lights

-

1.5 kW

heater with automatic temperature control (start time: 6:00)

The following

assumptions have been made:

Heating:

Lighting:

The results

shown in the tables below have been arrived from a combination

of ESP-r simulations and calculations.

|

|

Annual energy demand

|

Lighting

|

191 kWh |

|

Heating |

1567

kWh |

|

|

For

a typical winter day (7:00 – 18:00) |

Thermal percentage

dissatisfied |

10.69%

(18.12% standard variation) |

|

Thermal comfort

1 |

10 h

|

1

Hours

per day where the dry resultant temperature lies between 20°C

and 22°C

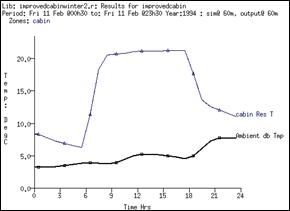

Pictures below

demonstrate the dry resultant temperature inside the

subcontractor’s cabin for a typical winter day. The upper line

shows the dry resultant temperature, the lower line shows the

ambient temperature

Ambient and

cabin’s dry resultant temperature

It is shown

that a dry resultant temperature above 20°C is maintained

between 8:00 and 18:00. Thus, the cabin of improved standard

provides a comfortable working environment for subcontractors.

Back to Top

The following

two tables summarise all results gained from the case study for:

Energy

Savings and Investments