Building Integrated Photo-Voltaic Technology

Photo

voltaic technology is a renewable technology which converts the suns energy

into electrical energy. PV technology was originally developed at the bell labs

in 1956 and is derived from the Greek prefix “Phos” meaning light and Volta

after Alexander Volta a pioneer in the field of electricity. PV has been around

for many years and has been used in applications such as providing power for

remote telephones and remote research units for many years, these applications

are often low in electrical demand. Other applications such as PV’s used to

power the electrical demand for satellites have helped blaze a trail towards PV

use into a more efficient, robust,

rounded economically viable technology.

How does PV work?

The

principal behind PV technology is the ability of the photons contained within

the suns rays to cause electrons to be moved to a higher energy level or orbit

so that they are free and are capable of conduction. The energy required for an

electron to jump to the next energy level is commonly known as the band gap

energy denoted generally by Eg. Materials have their own Eg value and silicon

which is the material used in most PV applications has a band gap energy of

1.12eV.

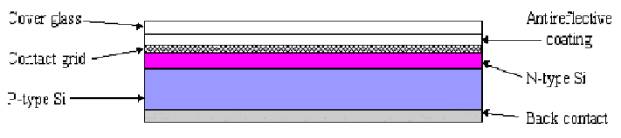

PV’s are

made from semi-conducting material which has been doped with a different atom

or impurity. Within the PV there are two layers, there are know as the p-type

and the n-type layer or the positive and negative layer. The materials used in

the manufacture of silicon have four electrons in the outer electron shell. The

impurity is added to the base material such as silicon which has either one

electron more in the outer shell or one electron less. The commonly used term

for this process is called doping. The result of doping is the creation of

places within the crystalline structure of the base material which have an

excess electrons (n-type) and places where there is a missing electron or a

deficiency (p-type). The missing electron is known as a hole or in other words

a positive charge carrier, while the extra electron acts as a negative charge

carrier. The most common material used in the manufacture of PV is the element

silicon which is one of the most abundant elements on earth. Some of the other

material used in the manufacture of PV are cadmium and gallium. The PV is

composed of the p-type material on one side and the n-type material on the

other side, this creates what is known as a p-n junction. Current flows in the

PV cell when an electron in promoted through the absorption of a photon. The

interaction of photons and the atoms in the PV are essential to the operation

of the PV, with out sunlight then there is not excited electrons and thus no

current. The amount of energy the photon must contain in order to excite an

electron must be greater the band gap energy Eg which is specific to the

material. The energy contained with a photon is a function of the frequency of

light and planks constant h (6.626*x 10-34). This it can be said that the

efficiency of the PV module is dependent on the intensity of light (W/m2)

intercepted by the cell. The stronger the light (the higher the intensity) the

more chance of the absorption of a photon to create an electric current. The

efficiency of the system is governed by the percentage of incoming photons

which cause absorption. Most of the photons absorbed by the cell do not contain

greater than the Eg value required and thus only increase the temperature of

the cell.

BIPV

technology differs somewhat from other application of PV where there are

different criteria. One of the most important considerations of BIPV technology

is its ability to be both a building façade as well as an electricity producing

technology. This can be a used as a very strong economic motivating factor as

the perceived cost of the system is reduced due to the elimination of the need

for other cladding. Design of BIPV really requires an all encompassing approach

towards building design, the various energy systems used within the building

and their interaction together. In this way the maximum benefits of BIPV can be

reaped.

The amount

of electrical power which can be obtained from a BIPV system is directly

related to the availability of solar radiation, this means the orientation, the

tilt and angle and the area of PV façade are of critical importance. The system

should be design so that the demand profile of the building is matched as close

as is possible to the supply profile from the system. This will have direct

effects on the necessity for Balance Of System components such as battery’s and

inverters. The economic viability will be highly dependent of the cost of

electricity from the utility company and the electric loads within the

building.

As with

the other integrated renewable technologies an understanding of the basic

principles of BIPV is essential to produce a BIPV design which does justice to

potential of BIPV at the particular site and building in question.

One of the

key factors which positively influences the case for BIPV in commercial

applications is the ability of the BIPV in some applications to closely match

the supply and demand profiles both daily and throughout the year.

The three

main types of materials used in for PV modules are

- Monocrystalline or

single crystalline silicon

- Polycrystalline or multi

crystalline solution

- Thin film

Mono crystalline silicon is usually produced by the Czochralski technique. This consists

of dipping a monocrystalline seed into molten polycrystalline. Once the seed is

removed a monocrystalline or single-crystalline crystal ingot is formed. The

ingots then go through many processes before finally ending up as a PV cell or

array. The main processes are sawing the ingots, doping, polishing,

interconnecting of the cells and assembly into PV modules and arrays. The

thickness of the wafers used for the manufacture of monocrystalline cells is

about 200 to 400 micrometers. The atomic structure of the monocrystalline is

very much an ordered structure. It is the high degree of atomic order the

allows the efficiency to be as high as 15%. Although real efficiencies will

certainly be lower than this. Monocrystalline cells tend to be reliable when

exposed to potentially harsh environments.

Polycrystalline silicon is manufactured using either the ribbon growth method where

silicon is grown as wafers or sheets which are around the same thickness as

that necessary for PV cell manufacture. Alternatively a block of

polycrystalline silicon is sliced to produce the size of wafer required. Unlike

monocrystalline cells the atomic structure of polycrystalline is not regularly

ordered. Polycrystalline consists of small grains of monocrystalline spread

throughout the polycrystalline. This means that as the flow of current or

electrons is reduced thus the efficiency of polycrystalline is lower than that

of monocrystalline cells. Conversion efficiencies of around 9 to 12% of likely

although real efficiencies are likely to be much less.

Thin film cells are

made by depositing thin semi conducting layer onto a substrate material such as

glass, metal or plastics. The light absorptivity of thin films is much higher

than for crystalline materials, thus the deposited layer can be very thin. The

thickness of the deposited layer is form a few micrometers to as little as one

micrometer. Generally the thinner the

deposited layer the cheaper the manufacturing costs. Spraying is often the

technique used for depositing the thin layer of the semi conducting material.

The manufacturing process for thin films as opposed to monocrystalline or

polycrystalline cells is much faster and uses considerably less energy. Thin

film cells have much lower efficiencies than crystalline materials. This is a

result of the non crystalline structure of the semi conducting layer. Much has

been talked of how thin film technologies can produce low cost environmentally

friendly electricity.

Amorphous silicon (a-Si) is by far the most commonly used thin film material. A-Si has a

disordered atomic structure. The main problem with a-Si apart from the low

efficiencies (real efficiencies of around 4% are likely) is the tendency for

a-Si cells to suffer from degradation on exposure to sun, wind, rain and

atmospheric pollutants. A-Si is likely to lose around 10 to 15% of their

electricity producing capacity within the first few months. A-Si cells tend to

oxidise and are thus much less durable than their crystalline counterparts.

Cadmium

Telluride (CdTe) is a polycrystalline semi conducting compound made from

Cadmium and Tellurium. The absorptivity of CdTe is high, thus CdTe can be as

thin as 1 micrometer and can absorb around 90% if the solar spectrum. CdTe is

also relatively cheap to manufacture. The deposition of CdTe is usually carried

out by spraying, screen painting or high-rate evaporation. A conversion

efficiency of CdTe is likely to be slightly higher than for a-Si. CdTe suffers

from most of the same problems as a-Si such as reliability problems and

degradation or exposure to the environment.