Advanced

Glazing

Traditionally, windows have been produced from clear glass. This is ideal for light transmission but also enables a large amount of heat transmission and thus has a high impact on the energy demands of a building. Consequently, various glazing developments have been made to reduce the heat transmission of glazing. There is no single glazing type which will be suitable for all applications, so here are some of the options, some of which are already on the market, others which will take a few more years to be commercially available. In many cases a combination of the technologies can be applied to give the optimum solution.

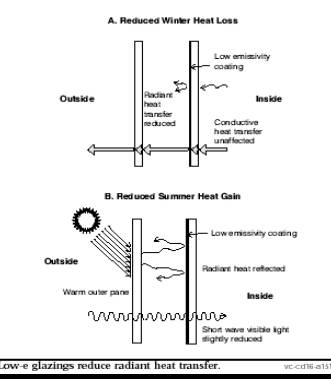

Low-e glazing is produced when one or more surfaces of the glass is coated with a thin metal oxide film. Often the coating is placed on the outer surface of the inner pane. This coating will reflect radiative heat back into a room during cold periods whilst reducing radiative heat gain during warm periods. The passage of light through the glazing remains largely unaffected, as does conductive transmission of heat. The oxide coatings are either hard or soft coatings. Soft coatings degrade when exposed to air so are not very durable. Hard coatings are extremely durable but do not offer as high performance as soft coatings. Spectrally selective glazings are a further development of low-e coatings. These coatings will reduce the heat transfer by 40-70% but will allow light to travel through the glazing. The coating can be customised to either increase or decrease the solar gains of the glazing, depending on the application.

Gas-filled glazing is fairly

self-explanatory. The gap between the

panes of glass is filled with an inert gas such as argon or krypton. The gases provide a greater amount of

insulation than air filled panes as conduction across the gap is reduced. Krypton has a lower conductivity than argon

but it is more expensive, so argon is most commonly used, alternatively a

mixture of the two gases can be used.

Gas-filled windows can be combined

with low-e coatings, highly insulating frames and double or triple glazing to

provide 'super windows', which provide a very high level of resistance to heat

transfer.

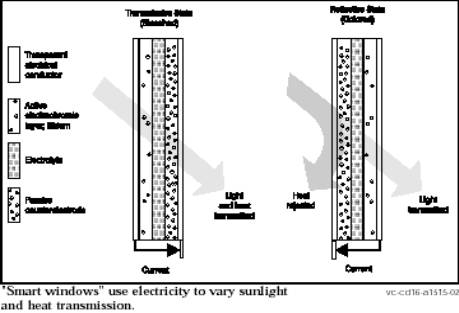

Dynamic glazing, or

'smart glazing', can vary its resistance level according to the conditions it

faces, that is, changes in light and heat intensity. This form of glazing is also known as chromogenic glazing and can

be separated into active and passive forms.

Active glazing, known as

electrochromic glazing, is controlled by a current passing through the material

to alter the amount of heat and light transfer. The state of the glazing is controlled by building occupants, who

set the current passing through the glazing and thus set the working

environment to suit their needs.

Passive glazing is

controlled by the external conditions to which a building is exposed. Photochromic glazing is that in which

resistance to light transmission across the pane is increased as the intensity

of light falling on the pane increases.

Thermotropic glazing increases its resistance to heat (or long

wavelength radiation) transmission as the intensity of the heat falling on the

pane increases. The disadvantage to

these passive glazings is that photochromic glazing may darken on a cold sunny day

and thermotropic glazing may darken when daylight to a room is more important

than a reduction in solar gain. In this

respect, the advantages of active glazing are apparent, namely the ability of

occupants to control their environment, without such a need to resort to

artificial cooling systems and artificial lighting.