1.

Single

sided ventilation can be effective for building widths up to twice the

floor-to-ceiling height.

2.

Well

designed windows are critical for minimum fresh air inflow in winter (trickle

ventilation to prevent cold draughts).

Horizontal pivoted and vertical sash windows have good ventilation

capacity, air enters at low level and leaves under buoyancy effects at high

level. Side or vertical pivoted windows are less effective.

3.

The capital cost of the mechanical services will be low

in buildings employing natural ventilation but considerably more may need to be

spent on the building fabric to achieve good thermal characteristics.

4.

A

naturally ventilated building has simple HVAC systems and as a consequence has

a low energy consumption. There is no

energy used for fans – air movement is achieved through well-designed opening

windows or more sophisticated ventilation stacks and flues which make use of

wind and buoyancy effects. The simplest of systems yields the lowest energy

consumption

5.

Windows and vents

which are to use for a single sided ventilation or cross flow system must be

considered in terms of embodies energy the embodied

energy contained within the materials.

A window frame which is made of aluminium and is specially transported

from Germany to Britain to be installed in a building would have a high

embodied energy that a window which was manufactured and installed within the

UK.

6.

Acoustic such as from outside the building very

difficult to control with single sided ventilation as a large amount of noise

will enter the building from opening a window.

Similarly the same noise may be able to enter through open vents. Depending on the size of vents and windows

noise may be generated from air moving through the opening. Noise reduction in single sided, cross flow

and stack ventilation can be achieved by good design of the system.

7.

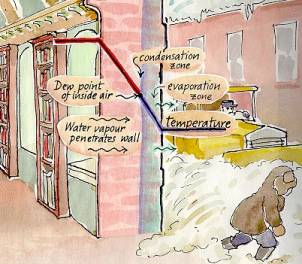

Condensation can be a factor in natural and basic

mechanical ventilation systems when the air, being vented or forced into a

building, has a high humidity and the temperature of internal surfaces are cold

thus causing moisture to condense to water on the surface.

8.

Single sided ventilation is only appropriate in small

areas. Occupants

near the perimeter will have control for single-sided ventilation and will

often feel the full benefit of the system before occupants at the back or

centre of a room. This system is

sometime not effective in providing adequate thermal comfort.

9.

Cross

flow ventilation can be effective for building widths up to five times the

floor-to-ceiling height.

10. Spatial room layouts are required in order to maintain

crossflow of ventilation air. The

position of large objects in a room can negate the effects of moving air in a

crossflow pattern.

11.

Depending on the design of the system, cross flow

ventilation can maintain a reasonable level of thermal comfort for the

occupants. However, there is a problem

for people close to the points of fresh air intake. If the occupant is static

for any long periods they may suffer from draught effects, especially since a

reasonable flow of air is required to induce the flow of air across a large

area. The indoor air quality can suffer

by this system as contaminated air is drawn across occupants’ bodies. Air quality can be a problem in urban sites as

filtration is difficult.

12.

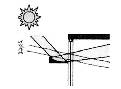

Stack Ventilation can be effective for buildings with overall heights up

to five times the floor-to-ceiling height, measured between the air inlet and

the stack.

13.

The

pressure generated by stack ventilation is too low for conventional air

filtration.

14.

Stack

ventilation can provide good thermal comfort and indoor air quality for

occupants. It achieves this by bringing

fresh air in at low level, cooling the

occupant, and as the warmed air rises (natural buoyancy) takes away any

contaminants in the air at high level. Air quality can be a problem in urban

sites as filtration is difficult.

15

More

building space is required to accommodate air handling plant and distribution

ductwork.

16.

Ducted distribution will permit ventilation

heat recovery, filtration and humidification

17.

Capital

costs are higher than for naturally ventilated systems due to the additional

expense of supply and extract fans, distribution ductwork and controls. The installation costs of the supply and

extract systems can be costly if there are long duct runs and complex

integration of systems into the building.

18.

With

a supply and extract system there is a demand for electrical energy to power

the fans. The electrical demand is

dependent on the size of the fans, the number of hours the fans run and speed

control on the fans to minimise the fan energy. There is an energy penalty for operating with high air flow rates

from the fans in the summer.

19.

Embodied

Energy – The embodied energy used in the manufacture of mechanical ventilation

systems is negligible to that of the energy consumed during the use phase

20.

Fan

energy can be significant, particularly if control of the operational hours is

poorly set-up. Design of a low energy

system will be effected in a negative way by fan operation has been poorly

controlled or there has been insufficient attention to the detail of the air

distribution pressure drops.

21.

The

design of the system is a very important factor in achieving good

acoustics. Where there are pressure

drops and large flow rates there can be noise associated with the supply and

extract system. This can be reduced

with acoustically insulated ducts and silencer baffles. However, it is primarily the designers responsibility

to ensure good acoustics from ventilation systems.

22.

Condensation can be a factor in basic mechanical

ventilation systems when the air, being vented or forced into a building, has a

high humidity and the temperature of internal surfaces are cold causing the

moisture to condense to water on the surface.

However, a

ducted supply and extract system can be used to supply winter humidification to

the space.

23.

A good filtration standard can be achieved with supply

and extract and hollow core ventilation, however, the penalty for higher air

cleanliness is capital cost for filters, maintenance costs and increased energy

required for fans. When compared to

natural ventilation solutions; supply and extract and hollow core can provide

more predictable performance giving improved environmental quality. In winter fans can operate with minimum

fresh air rates to control odour and stale air formation.

24.

Thermal mass can be used to cool or heat space and is

governed by the surface area which is available for heat exchange, the heat

transfer co-efficient between air and mass and the contact time. By moving air

through the structure itself, instead of just over it, has the potential to

improve all three factors and thus improve the effectiveness of available mass.

The system can be used throughout the year for thermal storage:

·

in summer, cooling is stored with night-time ventilation

of the mass, to be used the next day to cool the supply air before passing it

to the occupied space

·

in winter, waste heat from internal gains or heating can

be stored in the fabric to be re-used when the building has a heating demand.

25.

Hollow core ventilation systems have to be designed into

the building’s structure at an early stage as attempting to retrofit a

ventilation system capable of using a building’s thermal mass can be

impossible. The system requires

electrical energy to operate control systems and fan units. However, this system uses the natural

thermal storage ability of the building to heat or cool according to the

internal environment’s requirements and, hence, can reduce heating demand in

winter.

26.

It may be necessary to use condensation control on the

system to ensure the likelihood that moist supply air does not come into

contact with cold surfaces. This is

especially important in the design of this system as it uses surface energy to

cool or heat space.

27.

The system can be used throughout the year for thermal

storage:

·

in summer, cooling is stored with night-time ventilation

of the mass, to be used the next day to cool the supply air before passing it

to the occupied space

·

in winter, waste heat from internal gains or heating can

be stored in the fabric to be re-used when the building has a heating demand.

This system can optimise the thermal comfort

of the building.

28.

A

building can use a mixture of mechanical and natural ventilation, otherwise

known as mixed mode ventilation, to attain the best of both worlds. There are a number of design considerations

which could be used to optimise cooling of the building. The basic principle of this system is that

natural ventilation is used for Spring and Autumn with mechanical ventilation

used in the summer where necessary to augment the natural system. Mechanical ventilation can be used at night

to purge the building of heat build up from day use.

29.

A

special consideration for the system is to use exhaust air heat recovery.

30.

The

installation cost of this system can be minimised if natural ventilation is

designed to be used more predominantly than mechanical ventilation.

31.

With

a mixed mode system the requirement for fans can be reduced which means a

decrease on electrical demand. If heat

recovery is employed this can minimise the heating energy consumption.

32. The embodied

energy may be lower for a system such as this as the amount of mechanical ventilation

in the system is likely to be less for a building which uses purely mechanical

ventilation. The reason for this would be a reduction in ductwork and fans.

However, their may be an increase in the embodied energy associated with

controls in this system as it would require reasonably intelligent controls to

ensure effective changeover between systems.

33. The control of acoustics with this system may

be more difficult to control than the previous mechanical ventilation systems

described. As mixed mode systems employ

natural ventilation as a cooling strategy achieving good acoustics becomes more

complex. If opening windows or vents is

part of the natural ventilation strategy it is very difficult to control the

noise of airflow through the building.

34. Problems can be caused with opening windows if the occupants are

not clearly informed as to when the system changes over from mechanical to

natural ventilation, but there are psychological advantages in allowing

occupants control over window opening for at least part of the year. If the mixed mode system is designed

properly it will provide a comfortable internal environment for occupants with

good indoor air quality and thermal comfort.

35. Where daylight is present, the photocell sensors can interact with

the ballasts to fully utilise available natural light varying the luminance

continuously, with changes in natural lighting, to achieve a constant

illuminance on the working plane. The

benefits of this strategy vary from season to season.

36.

A high level of natural lighting must exist in the space in order for the

daylight sensing strategy to be

effective.

37. Daylight sensing

control is a very expensive lighting control strategy.

38.

It has been suggested that Daylight sensing control can save as much as 75% by whom of the running costs of fluorescent and

triphosphor lighting.

39. Daylight sensing offers relief to eyestrain. Eyestrain occurs when the muscle of the eye

continually adjusts to the brightness. However,

with daylight sensing it is the artificial lighting which continually adjusts

so that a constant illuminance is achieves for the occupant.

40. Occupancy sensors react to variables like heat or motion by turning

lights on or off. They turn lights on when the presence of people is detected;

then, after an adjustable predetermined period during which people are not

detected, turn them off. Because occupancy sensors prevent lights from being

left on when they are not in use, they conserve electricity. Occupancy Sensors

are most effective for those rooms or spaces which are not used for long

periods of the day. The benefits of occupancy sensors is that they are not

dependent upon users switching off lights which very often they forget to do.

PIR sensors are often effectively installed in toilets.

41. Occupancy sensors should not be installed in areas or spaces where

the health and safety of occupants are put at risk eg areas where there is

machinery operating. They are most

appropriate for controlling both incandescent and rapid star fluorescent lamps.

42. Passive Infrared

Sensors (PIR) are the most common type. They detect infrared heat energy

emitted by people. Triggering occurs when they detect a change in infrared

levels, as when a warm object moves in or out of view of one of the sensor's

"eyes." PIR sensors are passive: they detect radiation but do not

emit it. The cost of PIRs (not including installation) range from around £20 to

£70 depending on the type ie wall mounted or ceiling mounted.

43. Occupancy Sensors have the potential to significantly reduce

lighting energy consumption in proposed commercial and industrial

facilities. In a new building the

savings produced by occupancy sensors can be calculated by the amount of hours

the lights will be off according to occupancy against conventional lighting

systems on or off and reliant on human control.

44. It has been suggested that Daylight sensing control can

give potential energy savings up to 50% (Best Practice Programme) of the

running costs of fluorescent and triphosphor lighting.

45. High Frequency

(HF) electronic ballasts instead of conventional magnetic ballasts provide more

light output with less wattage and run much quieter and cooler. HF ballasts are most effective in reducing

energy consumption when used with energy efficient lamps.

46. The cost or an HF ballast is difficult to quantify for all

types of lighting. However, as a

guideline; three lamps, 4ft in size, fitted onto a triple HF ballast would cost

a maximum of £30 per triple ballast.

47. Fitted with HF ballasts, lamps would consume only 75% of the

energy they would consume with ordinary fittings.

48. HF ballasts produce

tens of thousands of pulses per second, causing phosphor to drop by 2%, and,

hence, light output to drop marginally from lamps. By comparison, traditional ballast produce 120 pulses per second

causing phosphor output to drop drastically resulting in lower illuminance

levels from lamps. With HF ballasts the

light flickers, which can sometimes be noticed by the naked eye in conventional

ballasts, does not occur.

49. Compact fluorescent (CF) lamps come in many shapes and sizes

and almost any fixture can be retrofitted which gives the building occupier

scope to change lamps design. They are

most effective and efficient where lights are on for long periods of time.

50. The ambient temperature can have a significant effect on

light output and lamp efficiency. The temperature of the coldest spot on the

surface of the lamp is where mercury vapour will condense to liquid form, and

this temperature (minimum lamp wall temperature) controls the vapour pressure

inside the lamp. The optimum lamp wall temperature for CF lamps is generally

38C. At temperatures below the optimum, mercury vapour will condense at the

cold spot, reducing the number of atoms available to emit UV radiation and,

hence, light output reduces.

51. A CF lamp has a life of around 8000 hours, hence reducing

the capital cost of changing the lamps against incandescent lamps. A CF Lamp is

a more expensive lamp than an incandescent lamp.

52. CF lamps typically reduce electrical use by around 25% on

incandescent lamp (conventional lamps with tungsten filament) use. CF lamps have a luminous efficacy (uses less

power in to provide light) of 70 lumens per watt.

53. For reasons of lumen maintenance, rare earth phosphors are

required in CF lamps.

54. Compact fluorescent lamps provide a colour-rendering factor

of 82 out of 100. They have a cool operating temperature so they do not enhance

heat gains in an area and thus do not impact on thermal comfort in an area.

55. Compact fluorescent lamps provide a

colour-rendering factor of 82 out of 100.

They have a cool operating temperature so they do not enhance heat gains

in an area.

56. A triphosphor lamp

has a life of between 12,000 and 18,000 hours, hence, reducing the capital cost

against continually changing the lamps against shorter life-span lamps. A

triphosphor lamp is more expensive than a CF lamp.

57. Triphosphor Lamps use 10% less electricity than a CF

lamps. The Triphosphor Lamp has a

luminous efficiency of 100 lumens per watt.

58. A higher content of rare earth phosphor is required in

triphosphor lamps than that of CF lamps. As the colour rendering index of

various types of triphosphor lamps increases so to does the phosphor

content. This inevitably has an adverse

effect on the embodied energy of this type of lamp.

59. The colour rendering index (reflects how accurate the colour

of an object can be determined under a given light source) for T8 Triphosphor

lamps is 85 out of 100.

60. T8 Triphosphor

lamps colour rendering index (reflects how accurate the colour of an object can

be determined under a given light source) of 85 out of 100.

61. Prismatic Panels

Prismatic Panels

are a shading systems using diffuse skylight.

Prismatic panels can be attached to vertical windows and skylights. The illustration above shows that prismatic

panels prevents direct solar radiation from entering the building whilst

accepting diffuse skylight. Prismatic

panels most effective use is in providing glare protection.

62.

The view to the outside environment can be restricted if the prismatic panels

cover the entire façade. Prismatic Panels are effective in all climates.

63.

Result in reduced solar heat gain and, hence, cooling and reduction in amount

of artificial lighting.

64.

With its ability to prevent direct solar radiation the prismatic panels provide

good daylighting whilst maintaining good thermaL

comfort

and glare resistance for occupants

65.

Anidolic Openings

There

are three main types of anidolic openings:

·

The zenithal opening,

(the first illustration from left to right), can be attached to skylights to

provide homogeneous illumination and glare protection.

·

The integrated

system, (the second illustration from left to right), can be attached to

vertical windows to provide lightguiding into the depth of a room and

homogeneous illumination.

·

The Anidolic Ceiling,

(the third illustration from left to right), can be attached to a vertical

façade above a viewing window to provide lightguiding into the depth of a room

and homogeneous illumination.

66. Anidolic Openings

are effective in reducing the amount of artificial lighting in localised

rooms or areas, resulting in reduced

electrical loads.

67.

Reduction in amount of artificial lighting.

68. Anidolic Openings are products still in the testing

stage.

69. With anidolic openings still at the testing stage it is

uncertain whether they can provide adequate human comfort. It seems however, that they will offer

good daylighting to localised areas

whilst rejecting

heat gain.

70.

Louvres and Blinds

Louvres and blinds are shading

systems from direct sunlight and can be attached to vertical windows. The illustration above shows that louvres and

blinds prevent direct solar radiation from entering the building whilst

allowing a proportion of diffuse skylight into an area. Louvres and blinds are most effective in

providing glare protection.

71. Louvres

and blinds can be used in all climates.

72. Louvres

and blinds will reduce the need for artificial lighting. However, through heat absorption, from

direct sunlight through the blinds, it may increase the need for cooling.

73. Louvres

and blinds absorb some of the solar radiation and transmit the heat into the

area causing discomfort for occupants in a room.

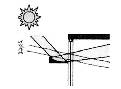

Lightshelf

A lightshelf is used to redirect direct

sunlight into a room by attaching it to a window, as is shown in the above

diagram. The lightshelf can provide homogeneous illumination and lightguiding

into the depth of a room.

74. Lightshelfs

are most effective in temperate climates with cloudy skies.

75. Reduces

the need for artificial lighting in deep set rooms.

76. Provides a very effective source of daylighting.

77. Light

Guiding Glass

Light

guiding glass can be effective in all climates.

78. A special

consideration for light guiding glass is that it can reduce the need for

artificial lighting in deep-set

rooms.

79. Provides an effective

source of daylighting which can reduce the need for artificial lighting

and, hence, the electrical load.

80. N/A.

81. Timbers - Wood is a complex organic

polymer, when used as a building material it may need to be protected against

termites (subterranean), wood destroying fungi, marine borers, wood boring

insects, the weather and fire. This is especially true in hot and humid

climates, or whenever timber comes into contact with the ground or moisture.

For timber that is not naturally durable, a preservative treatment might be

considered to extend its service life. Treatment can be viewed as a means of

conserving a natural resource and extending the overall life expectancy of a

timber. However, preservative chemicals in treated timber are often perceived

to be hazardous to handle and to the environment. The use of treated timber can

be minimised through proper design, and species selection. Interior timber does

not need chemical treatment if appropriate termite barriers and dry conditions

are provided. It is possible to determine whether or not treated or untreated

timber is required. The decision must be based on professional judgement that

considers many factors, some of which are, the presence of a hazard (moisture,

insect, decay, chemical, etc); the degree of structural reliability required

(loadsharing or non-loadsharing, the cost of failure and if failure occurs the

potential for death or injury); the desired or expected service life of the

structure; the natural durability of the timber (resistance to decay or insect

attack); the type or design of the building or component; the presence of

sapwood (only sapwood can be effectively treated unless the timber is

mechanically incised). Many structures can be designed so that treatment is not

needed. This can be achieved by protecting the elements behind cladding that

can be replaced easily.

Hardwoods:

Mahogany/Oak: Tend only to be used for finishing’s, suitable for window

frames, doors, door frames, flooring in domestic and commercial environments,

High quality flooring finish and because of the subsequent expense and is

normally used in Museums, Concert Halls, Function Rooms, Castle and upmarket

residences and Hotels etc.

Softwoods:

Pine/Spruce: Suitable for commercial applications - roofs and trusses,

engineered multi storey projects, domestic applications - boundary and

retaining walls, decking and structural skeleton.

Bamboo: Suitable

for flooring, walls, roofs, exterior/siding, framings doors.

82. Installation is inexpensive.

83. No effect-electrically.

84. When the source of timber is close, and the

number of links in the supply chain are few, it is easier to directly assess the

environmental impacts and take responsibility of the use of the timber in

question; buyers are generally in a better position to influence the practices

of the supplier, less energy and resources are consumed in transport,

packaging, shipping and other processes. Bamboo is a fast growing grass that

can be harvested in three to five years. Cork is a natural flooring material

that is obtained from the outer bank of the cork oak tree that is regenerated

every 10 years and is therefore Carbon Neutral. Using rapidly renewable floor

substitutes reduces pressure on hardwood forests.

Hardwoods:

Mahogany/Oak: Available in UK.

Softwoods: Pine: Available

in UK.

Bamboo/Cork: Available

in countries such as China, USA and Australia, would then require to be

imported to the UK so would involve high amounts of embodied energy.

85. Materials

are Sound Absorbent.

86.

If required

materials can be treated to protect against condensation effects, see section

81.

87. Materials will

increase thermal comfort in the winter also in the summer if adequate

ventilation systems are installed.

88. Concrete- Suitable for use

in domestic and commercial buildings, can be used in walls, flooring; for

flooring applications use is especially appropriate in a commercial environment

where floors are required to support heavy structural loads such as plant.

89. Standard

building material, installation is inexpensive.

90. The materials

themselves have no effect on thermal comfort, if insulation is high quality

will increase thermal comfort

91 The water, sand and gravel

or crushed stone used in concrete production is abundant. A Typical residential

use concrete mix is in the proportions of Portland cement 12 per cent, sand 34

per cent crushed stone aggregate 48 per cent and water 6 per cent. With all

these raw materials, the distance and quality of the sources have a big impact

on transportation energy use, water use for washing.

As such a

large amount of embodied energy is used in the manufacture of concrete measures

may be incorporated elsewhere in building design in an attempt to reduce

embodied energy such as, using exposed concrete as a flooring material

consequently eliminating the need to use other flooring materials. In other

words using additional flooring materials may needlessly increase embodied

energy.

92. Concrete floors and walls can cause moisture problems,

particularly in humid and wetter climates and leads to mould and mildew growth

which can cause significant health problems. Good drainage around a structure,

the use of damp proofing or waterproofing, effective ventilation and the use of

insulation can alleviate these problems.

93. Little effect on aesthetic

comfort, no effect on lighting comfort, will improve thermal comfort provided

there is a good standard of ventilation, waterproofing and insulation.

94. Aerated Concrete floors and walls can cause moisture problems,

particularly in humid and Wetter climates, and lead to mould and mildew growth

which can cause significant health problems in certain individuals. Good

drainage around a structure, the use of damp proofing or waterproofing,

effective ventilation and the use of insulation can alleviate these problems.

95. Marginally more expensive than standard concrete.

96. The thermal properties inherent in Aerated Concrete can lead to

lower heating demands.

The thermal qualities of

Aerated Concrete.

The thermal qualities of

Aerated Concrete.

Insulation quality can be improved using Aerated

Concrete blocks. Their inherent thermal qualities can provide an effective

barrier against the penetration of moisture and frost, the Figure 0.0.

Illustrates this. If used below the ground, Aerated Concrete blocks can reduce

heat loss by up to 25% compared to other forms of construction.

97. The water,

sand and gravel or crushed stone used in any concrete production is abundant. A

typical residential use concrete mix is in the proportions of Portland cement 12

per cent, sand 34 per cent, crushed stone aggregate 48 per cent and water 6 per

cent.

With all these raw materials, the distance and quality of the sources have a

big impact on transportation energy use, water use for washing. As such a

large amount of embodied energy is used in the manufacture of concrete measures

may be incorporated elsewhere in building design in an attempt to reduce

embodied energy such as, using exposed concrete as a flooring material

consequently eliminating the need to use other flooring materials. In other

words using additional flooring materials may needlessly increase embodied

energy.

98.

Lightweight concrete is commonly used for internal,

load-bearing walls where thermal and sound insulation are important.

considerations.

99. Use

of Aerated Concrete floors and walls can cause moisture problems, this is most common

in humid and wetter climates, and lead to mould and mildew growth which may

cause significant health problems in certain individuals. To alleviate these

problems good drainage around a structure, the use of damp proofing or

waterproofing, effective ventilation and the use of insulation is paramount.

100. No impact on visual

and aesthetic comfort, creates a good impact on thermal comfort with provision

of good ventilation system.

101. Metals-

Copper and Zinc can be used in electrical wiring, plumbing and heating applications,

Zinc can be used for guttering, Aluminium can be used for internal finishing’s,

roofing - If roof is pitched then Aluminium a suitable material to use, on a

flat roof a poly-membrane or asphalt covered roof is recommended.

102. Commonly used materials, installation is

inexpensive.

103. No

effect-electrically. Depending on the level of sunlight the material is going

to receive it may be coloured light or dark, the rule of thumb is when using in

hot countries it should be light to reflect the sun and dark in cooler

countries to absorb heat, this aids reducing heating loads.

104. The manufacturing processes involve large amounts of

embodied energy.

ALIMINIUM - Although Aluminium is relatively

easy to recycle and efficient recycling will permit the embodied energy in the

metal to be used again and again. Aluminium may well last the lifetime of the

building and may require smell levels of maintainance. It does not require

painting, or special treatments to prevent dry rot, fungus attack and rust.

Aluminium does not suffer from the effects of termite attack and therefore does

not require application of insecticides to the building or its surrounds.

The manufacture of aluminium involves

high-energy use, though this can be offset to some extent by utilising its

special characteristics to reduce the amount of metal used or to extend the

durability of structures or items it is to incorporate. The heat involved in

manufacture could also be conserved. Providing the design or construction

approach does not make it impossible to recover the material in a reasonably

unadulterated form, the potential for recycling aluminium is considerable.

Recycled aluminium requires about 5 per cent of the energy required to

manufacture primary metal and therefore recycling is a significant factor to be

considered in any life cycle approach to material selection.

The thermal energy required at

most stages of the production process and the large quantity of electrical

energy for electrolysis make aluminium one of the most energy intensive

materials. Over 125MJ of energy is required for each kilogram of primary

aluminium. The energy required to produce semi-fabricated aluminium products,

such as sheet or extrusions, is about 15 per cent that required producing the

primary metal ingots. Further processing, coating, fabrication and transport

results in a PER of 170 MJ/kg for aluminium building products.

ZINC - The raw materials used to manufacture lead

zinc include: lead and zinc ores, usually sulphides, coke, lead anode and

aluminium cathode materials for electrolytic zinc production.

Lead and zinc ores often occur

together and in association with metals such as copper and silver. The common

ores are sulphides and the production processes have some similarity to those

for copper, liberating SO2 and producing a concentrate for

subsequent production of the metal. Sulphuric acid is formed from the SO2

and is a useful by-product.

COPPER - The raw materials used to

manufacture copper include: copper ores, usually sulphides, froth flotation

reagents, siliceous fluxes, alloying metals such as tin, zinc and smaller

quantities of manganese and lead. Processes in the production of copper

include, copper ores are usually crushed, ground and concentrated at the mine

site by a froth flotation process. This stage is energy intensive and may

consume 100 MJ for each tonne of ore; concentrate, (containing 27-60 per cent

copper, 25-35 per cent sulphur, 25 per cent iron and 10 per cent water) is

transported to the smelter;

concentrate is mixed with

siliceous flux and roasted to about 650úC, liberating most of the sulphur as SO2;

and calcined material is mixed with additional siliceous flux and smelted in a

coal fired reverberatory or electric furnace to produce copper matte containing

about 45 per cent copper and slag. Flash furnaces combine the operations of

roasting and smelting and are more energy efficient but also liberate gases

with higher quantities of SO2. Depending on the technology employed,

the smelting state consumes 7-20 MJ/kg of copper (Biswas and Davenport 1980,

p.344).

Smelting involves the following

processes, slag from smelting is treated in an electric slag cleaning furnace

to recover the copper, or it is dumped; molten copper matte is converted to

blister copper (98.5-99.5 per cent pure) by mixing with siliceous flux and

scrap copper and blowing oxygen through the mix, liberating the remaining SO2;

fire refining at about 1100oC or electrolytic refining further purifies the

copper to 99.95-99.97 per cent pure (refining requires about 3 mj/kg of

copper); and fabrication of copper products.

105. If well insulated can

increase thermal comfort. No effect on aesthetic comfort though this is a

subjective view. When placing aluminium’s care should be taken they are not

badly placed which will routinely result in sunlight being reflected into

peoples eyes causing visual discomfort.

106. Poly-Membranes.

Generally used as a covering material on flat or pitched roofs. A Problem that

can occur in large flat commercial roofing applications such as a sports Hall

is that Large amounts of water may gather, which can be damaging to structural

strength of the roof, well-designed roofs should be specially designed to run

this water off.

107. Inexpensive.

108. No

effect-electrically. Colour of the material is important if the material is to

be used in a hot country it should be light coloured to reflect sunlight and

keep the building cool, in cooler countries it should be dark to absorb heat

which will aid in reducing heating loads.

109. The manufacturing

processes involve large amounts of embodied energy; the effects on

CO2 emissions

are highly negative due to the manufacturing processes.

110. The

chemical composition of the material if high quality protects against

condensation.

111.

If well insulated little or no effect on thermal comfort, no

effect on visual comfort, though is aesthetically acceptable, again a

subjective view.

112.

Cellulose

insulation is formed primarily from recycled paper products, such as used

newspapers. It can be applied to both

new buildings and retrofit projects as the material is applied by loose spray,

such that a jet gently fires it into place.

It is suitable for use in loft spaces as well as for wall insulation.

113.

Application

of cellulose insulation to retrofit wall applications would be difficult

without completely dismantling the wall for access. During its application the insulation causes a dust hazard but

mixing the material with some water prior to spraying can reduce this.

114.

The

installation cost is low as not only is the recycled material relatively cheap,

but the loose spray method of application is simple.

115.

Cellulose

insulation has very high insulative properties as it can be applied with

varying density. It can also greatly

reduce air leakage from the building envelope.

Consequently, the heat losses from a building and thus the heat demand

are greatly reduced.

116.

Cellulose

insulation has a very low embodied energy with the energy used in its

production quoted to be well over an order of magnitude less than for other

insulation materials. The material is

all recycled paper, which, once used, could again be recycled or allowed to

biodegrade. Resources of recyclable

paper are widely available so can be sourced locally to the project, minimising

the need to transport. There are no

CFCs or VOCs used in production thus eliminating emissions. However, the insulation material must be

treated with inorganic salts to protect against any fire hazard and also make

the material resistant to fungal attack.

These salts are boron salts, which are in limited supply and must be

mined. Additionally, the only mines of

boron are in the US and Turkey so the boron is transported over very long

distances.

117.

Cellulose

insulation is already commercially widely available, although not on the same

scale as fibreglass. Reliable

information on its performance is scarce, particularly for wall insulation.

118.

The

properties of insulation are such that sound is insulated against as well as

heat. The effectiveness of materials to

insulate against sound follows the same trend as their ability to insulate

against heat, such that cellulose has the greatest effect, followed closely by

fibreglass and then plastic foams. The

credentials of Air Krete are not well documented, but if it lives up to claims

then it should provide a high level of insulation towards sound. Transparent insulation, reportedly, also

performs well as an insulator to sound.

119.

Water

vapour in the air can be carried into insulation by air leakage through

walls. To prevent this problem air

leaks need to be sealed. This is often

done by applying a layer, which is impermeable to water, to the warm side of

the insulation, such as a polyethylene film or oil based paints.

120.

Insulation

improves the thermal comfort of a room, whilst helping to keep out unwanted

noise. Indoor air quality may be

negatively affected when air passage is prevented to too great an extent. A good ventilation system would of course

solve this problem. The limited amount

of research has not shown there to be any harmful gaseous releases, even from

the fire retardants.

121.

Fibreglass

is the most common type of loose fill insulation used. It is supplied in blanket form and is rolled

out into place. Consequently,

fibreglass can be used in lofts and walls and for both new build and retrofit

applications.

122.

Fibreglass

is widely available and the cheapest insulation material, both to buy and

install. .

123.

Insulation

properties are high, although quoted as lower than cellulose. However, heat demands will be significantly

reduced.

124.

The

embodied energy of fibreglass is quoted as being an order of magnitude greater

than that of cellulose. It is produced

from molten glass, which is spun into long fibres and bound together. This is quite an energy intensive

process. Fibreglass insulation can

include a proportion of recycled glass.

No CFCs are used during manufacture.

Resources are widespread so can be sourced near to the project location,

minimising the transportation required.

125.

Fibreglass

is seen as a standard insulation material with no known defects, thus

uncertainties associated with its use are minimal

126.

It

has been suggested that fibres that may be released from fibreglass are

carcinogenic, although research is conflicting, as some research states that

indoor air quality is not significantly affected by the fibres. The thermal comfort of building occupants

will of course benefit.

127.

Plastic

foams such as polystyrene, polyurethane and polyisocyanurate are widely used as

insulation materials. The insulation is

in the form of a blanket which can be laid out in loft spaces or installed in

walls.

128.

Plastic

foams are a widely available and reasonably cheap material, both to buy and

install. Having been on the market for

a long period of time, the price of this insulation compares favourably with

other types available.

129.

Plastic

foams have an embodied energy that is greater than cellulose by an order of

magnitude and higher than that of fibreglass also. Plastic foams are produced from valuable fossil fuel resources

and large amounts of energy are required in processing. The recycled content varies between foam

types but is never a significant percentage.

The location of material source should also be as close as possible to

minimise transportation. CFCs have been

used in manufacture up until recently.

130.

VOCs

are released from the plastic foams during their use affecting the indoor air

quality of a building.

131.

Air

Krete is an inorganic foam of magnesium oxide, which is derived from

seawater. Air Krete is foamed in place

behind the wall. The material is lightweight

but rigid and friable.

132.

Since

it is relatively new to the market, the cost of Air Krete is quite high.

133.

Insulative

properties of Air Krete are quoted to be very high, thus heat demands should be

significantly reduced but there is a lack of information to back up claims.

134.

The

embodied energy is lower than that for plastic foams but still higher than for

cellulose. No CFCs are used and VOC

emissions are low. The material comes

from the readily available source that is seawater.

135.

Information

on its recommended use and properties is not readily available, thus

uncertainties associated with its use are high.

136.

Transparent

Insulation differs from other insulation materials in that it must prevent the

passage of heat whilst still allowing solar energy to pass through. Applications include the insulation of solar

collectors, use in Trombe walls and as a form of advanced glazing.

137.

Installation

costs are relatively high, mainly due to the complex applications of

transparent insulation, but also because the technology is still relatively

new.

138.

The

use of transparent insulation, for example, in Trombe walls reduces heating

loads. Solar radiation, that is short

wavelength radiation, is able to pass through the insulation, whilst long

wavelength radiation is reflected back into a room.

139.

Transparent

insulation is made from plastics.

Consequently it uses valuable fossil fuel resources and the amount of

energy required in processing is high.

It would be possible to include some recycled plastics. Again the location of such material has a

significant impact on the embodied energy.

140.

The

applications of transparent insulation are relatively new, thus not used widely

on a commercial scale. Although there

is some theoretical information on transparent insulation, its practical

application is neither proven nor well documented.

141.

Transparent

insulation releases heat into a room and prevents its escape, keeping

temperatures steady, thus the thermal comfort is improved. Visually it is useful as its insulative

properties can be utilised while still allowing natural light to enter a room,

to the benefit of visual comfort.

Trombe

Wall

142.

Trombe

walls are a form of solar heating, forming part of the building facade. Sunlight is absorbed by an external dark surface

and stored in the thermal mass of the wall.

Several variations are available, fitted with insulation, different

absorbing materials and storage materials with a larger heat capacity, such as

water.

143.

Trombe

walls are often difficult to implement in design as they conflict with building

requirements for view and access. The

wall should be south facing to gain the most sunlight but shading devices are

fitted to prevent overheating in summer.

Even with these shading devices, heat gain is difficult to control,

resulting in instances of overheating.

The construction of Trombe walls is such that high levels of maintenance

are required. Mechanical failure is a

persistent problem

144.

Installation

costs are high in comparison to that of standard structures. Trombe walls do not have a standard

construction procedure.

145.

The

use of trombe walls for heating in winter and cooling in summer will have a

marked effect on the electrical and heating requirements of a building. The heat from solar radiation is stored in

the wall for long periods and transmitted to the room several hours later, i.e.

at night. In summer, the wall can be

used to draw cool air through the room and in the winter, it provides space

heating.

146.

A

trombe wall uses a large number of materials, such as glazing and plastics,

which have a high-embodied energy. An

analysis of energy payback time would be required to justify their use. Materials which can be sourced locally would

be a better choice.

147.

Trombe

walls are not widely used commercially.

The theory behind them is well established, however, there are few

documented practical examples to verify its effectiveness.

148.

Thermal

comfort of occupants will be improved and air circulation will be improved.

149.

Breathable

walls allow high moisture permeability.

Thus higher amounts of moisture are able to migrate from the inside

structure to the outside structure.

There is no moisture barrier, such as the polyethylene film, which is

applied with standard insulation.

150.

The

materials used in a breathable wall are carefully selected to provide the

correct resistance to vapour flow thus enabling moisture to diffuse naturally

through the material. The inside

sheathing of the insulation material must have a greater resistance to flow

than the outside material so that moisture flows outwards and not inwards.

151.

Installation

costs are comparable with standard walls as the structure is fairly similar.

152.

Good

insulation properties will reduce heating duties. Greater airflow through the wall than that for standard structures

will remove heat from the building such that heating loads are not reduced to

quite the same extent.

153.

Breathing

walls often use cellulose insulation, thus the embodied energy can be lower

than for standard walls. (See section 116)

154.

Moisture

is allowed to pass through the wall in a regulated manner, so condensation

should not be a problem.

155.

As

with all insulation, the thermal comfort of occupants should be enhanced. Additionally, indoor air quality is enhanced

by the high level of diffusion of vapour and air through the wall.

156.

Phase

Change Materials with a melting point slightly above room temperature are used

in construction. They can be

incorporated into both interior and exterior walls, coupled with other

insulating materials or even combined with under-floor heating.

157.

PCMs

are also undergoing investigation into their use as a high-density storage

medium for energy gained, for example, from solar collectors. As with water storage tanks, adequate space

must be provided in which to situate the tank.

The inclusion of phase change materials within walls must be considered

from the outset so that safe loads upon the wall can be determined.

158. PCMs are only produced by a handful of companies and are still

undergoing a great deal of research.

Consequently, their cost is still high.

159.

PCMs

absorb and release heat as the temperature of the room rises and falls and thus

reduce fluctuations in room temperature and consequently reduce heating and

cooling loads. During warm hours of the

day, a PCM with the correct melting temperature will melt thus removing heat

from a room. This heat remains stored

in the material until the temperature of the room cools, upon which time the

PCM solidifies releasing heat back to the room. Here we can see that PCMs can be used to keep the temperature of

a room reasonably constant. Electrical

demands for daytime cooling will be reduced as will heating demands. PCMs combined with under floor heating are

used to release heat to a room steadily thus controlling both the temperature

of the room and reducing the amount of heating required. Hydrated salt PCMs have a higher energy

storage density than paraffins thus have a greater impact on heating and

electrical demands.

160.

Paraffins

have a higher embodied energy than hydrated salts. They are also produced from valuable fossil fuel resources. Both materials will involve high amounts of

energy in transportation as their manufacture is not widespread.

161.

The stability of PCMs is still variable and the benefits of

using either hydrated salts or paraffins and is still in debate. Consequently, there is still a high level of

uncertainty involved in the use of PCMs.

162.

The

temperature of a building can be kept at a more constant temperature thus

improving the thermal comfort of occupants.

Research has not shown any gaseous releases from phase change materials,

thus indoor air quality should not be affected. However, it should be remembered that paraffin PCMs are both

toxic and flammable, whilst hydrated salts are not.

163.

Low

emissivity glazing is applied where maximum lighting is desired but a greater

control over thermal gains is required, such that short-wavelength radiation

(visible light) passes through the glazing but longer wavelength (heat)

radiation is reflected back into the room or prevented from entering, depending

on requirements.

164.

Glazing

has a huge effect on the thermal gains and electrical demands of a

building. Particularly in modern

design, large areas of building facades are comprised of glazing for aesthetics

reasons. Glazing affects the light

available to the interior. This is

important when considering the use of daylighting. Orientation of glazed facades will affect their impact, that is

southerly facing facades will receive high amounts of solar radiation compared

with other orientations. The presence

of other buildings in the vicinity may affect the optimum use and placing of

glazing.

Of course, the more complex the

glazing, the greater its effect on building performance. Increasing the level of glazing to triple glazing

will restrict the passage of long and short wave radiation through it. The addition of a low-e coating will, in

particular, restrict heat gains and losses, as will an inert gas. The optimum solution may be to install

dynamic glazing hence enabling levels of lighting and heat gain/loss to be

adjusted to a user's need at a given time.

The choice of glazing depends very

much on the siting and in particular the orientation of the glazing. The choice

of frame must also be carefully considered in order to avoid thermal bridging.

165.

Installation

costs for conventional glazing are now becoming standard, and lowering as

competition between companies increases.

Triple glazing is often available from standard glazing companies but an

increase in cost reflects the increased complexity. Low-e coatings and gas-filled glazings are not widely

commercially available and thus costs immediately increase. Very often, it is not the material that is

expensive, rather from where it is sourced and its sophisticated installation. As a guide, the cost of low-e glazing is

estimated to be around 10-15% higher than that of conventional glazing with

costs increasing further with greater glazing complexity.

166.

As

already mentioned, the use of glazing can have enormous effects, both positive

and negative, on heating and electrical demands for a building. To begin with the negative problems; solar

radiation transmitted to a room will increase room temperature and increase the

need for cooling and as such increase electrical demands. Applying shading to these windows would

lower cooling duties but increase electrical demands for artificial

lighting. Standard glazing presents

these problems, however, as already stated advanced glazings begin to solve

these problems. Low-e glazings will of

course reduce solar gains to a room whilst still allowing light to enter. Consequently, cooling loads are reduced and

the windows can be used as sources of daylighting. Gas-filled glazing will provide a decrease in thermal losses or

gains to a building by reducing conduction through the glazing, thus heating

demands will be reduced in winter and cooling demands reduced in summer. Dynamic glazing, once again, would be ideal

as it can vary according to the outside conditions, thus reducing heating, cooling

and electrical demands at otherwise peak times.

167.

The

manufacture of glazing has an inherently high embodied energy. However, the amount of embodied energy will

increase depending on the complexity of the technology. The lowest embodied energy is found in

single glazing with wooden frames. The

embodied energy increases with the number of panes of glass along with the

choice of frame. The manufacture of

plastic and metal frames uses much greater quantities of energy than wooden

frames. Specialised glazings give rise

to a huge leap in embodied energy, as the processes to produce, for example,

low-e coatings are very energy intensive.

Specialised glazings are often transported over larger distances as

their manufacture is not widespread.

This will once again lead to increased embodied energy.

From a first look it would seem

sensible to use to simplest glazing possible in order to reduce embodied

energy. However, to compare the

glazings fairly, energy payback time must also be taken into consideration. The amount of energy saved by increasing the

level of glazing from single to double-glazing produces a very short energy

payback time. This energy payback time begins to increase somewhat as low-e

coatings are added, however they are still within reasonable levels. It is when we reach very complex glazing

strategies, in particular dynamic glazing, that energy payback times become

longer than the lifetime of the glazing, according to literature. It is then that the question must be asked

whether minimum energy use during the use phase out ways the vast amounts of

energy involved in manufacture.

168. Obviously, the use of more sophisticated

glazing increases the risk posed by the project. Dynamic glazings, also feasible in principle, are far from commercial

use. Their cost and the risk involved,

in technology more prone to problems, limits their use to demonstration

projects at present.

169. It is well known that increased glazing

will provide insulation against sound as well as heat. The greater the number of panes, the better

the insulation, thus triple glazing is better than double glazing. Use of inert gases, as in gas filled

glazing, will also result in a reduction in the transmission of sound across the

glazing compared with air-filled glazing, whilst low-e coatings will not have

any marked effect.

170. The use of advanced glazings can

dramatically increase human comfort within a building. Thermal comfort will be increased by reduced

heat gains and losses; visual comfort will be increased by greater use of

daylighting and reduced glare. Dynamic

glazing would have the greatest impact as glazing can respond to changes in

climate and also changes in user demand, in the case of active systems.

171. Gas-filled glazings are suitable in

applications where a decrease in heat losses from a building is of great

importance, for example in colder climates, where solar gains are not a

problem, if not desirable.

172. Triple glazing offers increased levels of

thermal insulation in comparison to standard double glazing and would be

applicable in colder climates where a tight building envelope with minimum heat

and air losses are desirable. Low-e

coatings and inert gases can be applied to triple glazing to improve its

properties.

173. Dynamic glazing is seen as a versatile

glazing for the future. Active glazing

enables building occupants to have total control over their environment and

passive glazing can adapt to the surroundings it is presented with. Consequently, these glazings could be

applicable to any situation.

174 Plasterboard is used for internal,

non-load-bearing walls, as well as for cladding of load-bearing walls.

175 Plasterboard is a standard building

material, used in most construction processes, thus costs are relatively low

and dependent on competition between companies.

176 Plasterboard cladding adds to the

insulation of external walls thus lowering heat demands. Partitioning with plasterboard also gives

smaller areas for space heating.

177. Plasterboard is produced from gypsum with

its production giving a moderate embodied energy. The gypsum may be mined, which is very energy intensive, or taken

as the by-product from chemical manufacturing, such as hydrogen fluoride

manufacture. This use of a by-product

would be less energy intensive as otherwise wasted materials are utilised, but

the gypsum would require purification, which requires energy. Before gypsum can be used as Plaster of

Paris in plasterboard manufacture, water must be driven off, once again

requiring the input of energy. Never

the less, the embodied energy of plasterboard is seen as being lower than for

bricks even when the use of insulation increases embodied energy levels.

178. Plasterboard is not well known for

insulating against sound, as is shown in many modern buildings. This could be improved by the addition of an

insulating material.

179. The main benefit to human comfort to be

had from plasterboard is increased thermal comfort from added insulation to

external walls. There is no known

release of toxins from the materials which could affect indoor air quality.

180. Bricks are the most widely used building

material, as they are versatile and can be built to withstand variable loads.

181. Bricks are available in a wide range of

sizes, shapes and colours to blend with surrounding buildings and

features. They combine well with other

building materials used in construction.

182. Bricks are a commonly used and reliable

building material, thus costs are low and vary due to competition between

suppliers.

183. Bricks have reasonably good insulation

properties due to air trapped inside.

Used in well constructed cavity walls, bricks help to provide a tight

building envelope so that heat demands are minimised.

184. The manufacture of bricks is an energy

intensive process, which involves the extraction of the clay and vast amounts

of energy to fire the kilns.

Additionally, bricks are transported in vast quantities over sometimes

large distances. The embodied energy of

bricks, together with their environmental impact is of concern, thus measures

have been taken to reduce these. The

extraction of clay is attempted in a sensitive manner so as not to have as high

an impact on the landscape. Kilns used

for brick firing are being developed to improve their efficiency. The recycling of bricks is being promoted

and brick deliveries are being synchronised to reduce the number of journeys

made by lorries.

185. Bricks provide a reasonable amount of

insulation against sound and, coupled with insulation materials, provide good acoustic

properties.

186. If the temperature of the bricks drops to

the dew point of water, the water will condense thus creating a moisture

problem within the wall. This can be

prevented by good quality wall construction, in which the internal face of the

wall insulation is protected by a moisture barrier, such a polyethylene film,

and the internal temperature of the wall is maintained above the moisture dew

point. For breathing walls, good

airflow through the wall should prevent condensation.

187. Bricks,

and more specifically, the structure of external walls will affect the thermal

comfort and indoor air quality of a building.

A highly insulated wall will of course aid in maintaining the

temperature of a building. The level to

which the building is air tight will affect the indoor air quality of the

building. Adequate ventilation must be designed for cases of a tightly sealed

envelope. Visually, bricks can be an

attractive external or internal feature.

188. Adobe Bricks are capable of withstanding heavy

loads, when thick walls are constructed, thus can be used in load bearing and

non-load bearing applications. Their

strength is not as great as that of conventional bricks, but their use is still

possible with steel and timber frames in building structures several stories

high.

189. The appearance of the Adobe bricks will

reflect their source as colours of clay and sand vary a great deal with

location. The use of the bricks in

their native area will produce buildings that blend well with the surroundings.

190.

The

cost of the Adobe bricks is relatively low but affected by intensity of labour

required in their production. Some

production on a commercial scale has lead to expensive products for this very

reason.

191. Adobe bricks have a high thermal mass but

are not great insulators as not much air is trapped in the structure. When required, linings can be applied to

increase levels of insulation. In the

warm climates where use of Adobe bricks is common, insulation is perhaps not of

great importance and the mud bricks actually help to keep a building cool, thus

lowering electrical demands for cooling.

192.

Clay

and sand used in producing Adobe bricks is sourced locally and of course the

energy used to dry the bricks comes directly from the sun so embodied energy is

low. The use of fossil fuels is

minimal, although large amounts of water are needed.

193. Although the use of Adobe bricks is not

widespread, it is now established, particularly in warmer climates. Consequently their performance has been

proven so uncertainties are low.

194. Adobe bricks have very high sound

insulation properties.

195. Adobe bricks require protection from

moisture, particularly from extreme weather conditions. The structural properties of otherwise

sturdy bricks can be affected by weathering or seepage of water.

196. Adobe bricks are essentially breathable

walls such that indoor air quality should be high. In some cases additional ingredients are added to the bricks to

protect them, such as bitumen. This can

cause emissions of hydrocarbons, which will of course have a negative effect on

the air quality. Although not good

insulators, the bricks provide good thermal comfort by keeping buildings cool

in warm climates.

RENEWABLE TECHNOLOGY SELECTION TOOL

PROBLEMS DEVELOPING THE HIGH LEVEL TOOL