Life Cycle

Assessment Material

1.What

is LCA?

Life cycle assessment (LCA) involves the evaluation of some aspect - often the environmental aspects - of a product system through all stages of its life cycle. Sometimes also called "life cycle analysis", "life cycle approach", "cradle to grave analysis" or "eco-balance", it represents a rapidly emerging family of tools and techniques designed to help in environmental management and, longer term, in sustainable development. This publication, developed for the European Environment Agency (EEA), aims to help business and other readers to find their way through the LCA maze to the right tools for the application they have in mind. The early chapters are written in such a way as to be easily accessible to environmental managers in companies and other similar professionals, whereas the methodology sections may require some LCA background of the reader.

2.What

is a historical flashback of LCA?

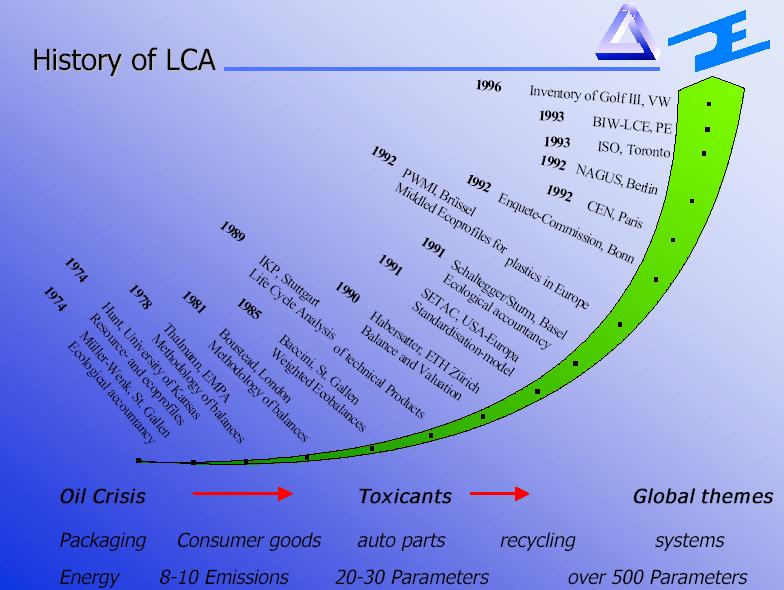

The first studies to look at life cycle aspects of products and materials date from the late sixties and early seventies, and focused on issues such as energy efficiency, the consumption of raw materials and, to some extent, waste disposal. In 1969, for example, the Coca Cola Company funded a study to compare resource consumption and environmental releases associated with beverage containers. Meanwhile, in Europe, a similar inventory approach was being developed, later known as the ‘Eco-balance’. In 1972, in the UK, Ian Boustead calculated the total energy used in the production of various types of beverage containers, including glass, plastic, steel, and aluminium. Over the next few years, Boustead consolidated his methodology to make it applicable to a variety of materials, and in 1979, published the Handbook of Industrial Energy Analysis.

Initially, energy use was considered a higher priority than waste and outputs. Because of this, there was little distinction, at the time, between inventory development (resources going into a product) and the interpretation of total associated impacts. But after the oil crisis subsided, energy issues declined in prominence. While interest in LCA continued, thinking progressed a bit more slowly. It was not until the mid eighties and early nineties that a real wave of interest in LCA swept over a much broader range of industries, design establishments and retailers - taking many of them by surprise. Despite almost three decades of development LCA is still considered a young tool by the majority of its practitioners. The rapid surge of interest in ‘cradle to grave’ assessments of materials and products through the late 1980s and early 1990s meant that by the 1992 UN Earth Summit there was a ground-swell of opinion that life-cycle assessment methodologies were among the most promising new tools for a wide range of environmental management tasks. The most comprehensive international survey of LCA activity to date, The LCA Sourcebook, was published in 1993. At the time, LCA was of limited interest “outside a very small community of scientists”, mostly based in Europe or North America. But then, the Sourcebook noted, “their work escaped from the laboratory and into the real world”.

Some countries took an early lead. “In the UK”, said David Cockburn of PIRA, “it has been surprisingly fast. Ten years ago there was only one main practitioner [in the UK], Ian Boustead. Now there are many more academics, consultancies and companies with an in-house capability”. While the field continued to progress, the pace has been sporadic. According to a recent report by IMSA and SPOLD, the chief barriers to greater progress in the LCA field have been a low level of experience with LCA, coupled with undue expectations and “over-advertisement”. This led to a period of disillusionment with LCA, aggravated by a strong sense that many of those using LCA were simply doing so to buttress existing positions, rather than to fully understand and respond to the real issues. So the question is, where are we now? Although the pace of development is slowing, the methodology is beginning to consolidate - moving the field toward a long-awaited maturity. Yet the usefulness of the technique to practitioners is still very much in debate. In the past couple of years, however, there has been a growing confidence in the LCA community that the emerging tools have a real future. For example, Procter & Gamble’s Peter Hindle sees “enormous progress” and is optimistic about the future for life-cycle inventories (LCIs) and about the take-up of life cycle thinking by management generally. Others take a very different view: “LCA is a million miles away from the man in the street”, said Dr Mike Jeffs of ICI Polyurethanes. Part of the difficulty in making the technique more accessible comes down to the competing needs of simplicity (or at least clarity) to aid practitioners and credibility, to enable decision-makers to have faith in the robustness of the results. As Mariane Hounum of the Danish Environmental Protection Agency put it: “We need to find a simple way of communicating the results of LCA, because most people have neither the time nor the interest to read entire documents. But if the answers are simple, then again the question of credibility arises - because there is no way for [stakeholders] to check the validity of the results”.

Back in 1992-1993, Sustainability coined the term “laptop LCA”, pointing out that until LCA as a tool becomes truly user-friendly and accessible, it is unlikely to take off in a comprehensive way. Over the years, software designers have been responding to the challenge, and as the final section of this Guide demonstrates, there has been a proliferation of LCA software on the market. These should be carefully checked before use, however, since this field is still in its infancy - and the available products are of variable quality. One of the key concerns is that it is often very hard indeed to verify the quality of the data used. Overall, the LCA community is now able to offer a growing range of useful management tools. But it continues to struggle a number of key issues, some of which are strongly linked to the nature of the discipline itself. These include:

· The complexity of many of the methodologies and processes;

· The high cost and long time-scales, although much progress has been made in this area;

· The necessity of making value judgments in the course of the work, judgments which are not always identified in the final report;

· The lack of accepted international standards (although the SPOLD LCA format initiative has been useful, and an ISO standard is under way);

· The continuing invisibility of much LCA work, compounded by the above factors.

But the lack of a real market pull for LCA data is perhaps the most important factor. Companies have simply not, by and large, felt the need for LCA in their regular decision-making. That said, however, and given the cooling of public opinion on most environmental issues through the mid-1990s during the second great environmental down wave, it is astonishing how much interest there has been in some sectors of industry. LCA results have played a key role in procurement decisions, for example, as companies have sought to assess the relative performance of competing suppliers. This activity, in many cases, has been driven by a recognition that while public opinion may move in great surge-tides, the underlying trend on most environmental issues is still moving steadily upwards. A series of issues in 1995 and 1996, most particularly the controversy surrounding the planned disposal of the Brent Spar oil buoy and the massive economic and social dislocations caused by public reactions to ‘mad cow’ disease or BSE, helped to re-ignite interest in life-cycle thinking, if not necessarily always in LCA methodologies proper. The Brent Spar debate highlighted the need to use LCA not only to fast moving consumer goods like detergents, or consumer durables like washing machines, but also to major structures and installations. Although Shell has conducted work on the ‘shadow pricing’ of the disposal options, many observers wondered why life cycle thinking had not been built into the design and operation at a much earlier stage. The BSE controversy, in turn, raised the life-cycle issue for a wide range of industries and for consumers, by illustrating how vulnerable agricultural and food chains are to new forms of contamination.

LCA has traditionally been written about and discussed by experts behind closed doors, or in the R&D laboratory, with little in the way of public communication, let alone consultation. But as practitioners see the need for increased credibility of the tool and greater acceptance by the public, the mood is changing. As a result, there is now a greater curiosity about what other people think about the discipline, and about the implications for the future. In order to develop an introduction which was topical and well-founded, SustainAbility conducted a sample survey of industry practitioners, standard setting organisations, eco-labelling boards, industry associations, research institutes, consultants, non-governmental organisations (NGOs), students, the environmental media and financial institutions. Their views inform the sections which follow.

The findings of the survey can be summarised as follows:

· LCA, in its various forms, is now seen by all stakeholders as a necessary, integral part of the environmental management took-kit;

· Practitioners see value in using this family of tools not only for established areas like new product development but also, increasingly, in the process of corporate strategy formulation;

· Although the period of "maximum hype" is over, LCA remains in the early stages of development, with a good deal of further development needed;

· The level of knowledge of LCA remains worryingly low in the public domain;

· Among those who are aware of LCA, there is still a clear divide between those who focus on LCA as a set of tools and those who consider LCA thinking as a paradigm through which to think and prioritise;

· The level of progress differs between countries, but overall the pace of development in the LCA field is slowing as consolidation of methodologies begins;

· The credibility of the tools - and of the users of LCA data - is critical if the LCA community is to gain sufficient authority and LCA is to be useful in the long term;

· A major concern - expressed by a high proportion of practitioners - is that quality control mechanisms remain relatively weak;

· The involvement of external stakeholders in defining study boundaries and stimulating ‘out-of-the-box’ thinking is seen to be increasingly important.

3.

Is

LCA mandatory?

In a word, no. LCA is currently an option for companies, but it is an option which growing numbers of customer companies are beginning to encourage their suppliers and partners to at least think about. In some countries, for example Denmark, new environmental accounting and reporting requirements are likely to encourage the further spread of LCA thinking, if not always of LCA tools. The use of LCA in the private sector varies greatly. This differentiation depends to a large extent on where a given company is situated in the product chain and on the key driver for the LCA activity, e.g. legislation or market competition. For business teams, the LCA tool should be used to understand the environmental issues associated with upstream and downstream processes as well as on-site processes. This understanding can be used for continuous improvement in reducing the impacts throughout the supply chain. Commodity producers (chemicals, plastics, metals) most often perform life cycle inventories to be used in comparative assertions or for assessing waste management and recycling options. Producers of intermediates and components provide data for their customers, and producers of final goods combine the knowledge from upstream and downstream processes to design and manufacture products with the least environmental impact. Time in this context, is an important factor in LCA. For companies producing final goods in a competitive market, the product development cycles are short and accordingly, comprehensive LCAs are not feasible with the presently available data bases because the analysis are time consuming.

4.What

Are the Benefits of Conducting an LCA?

An LCA will help decision-makers select the product or process that results in the least impact to the environment. This information can be used with other factors, such as cost and performance data to select a product or process. LCA data identifies the transfer of environmental impacts from one media to another (e.g., eliminating air emissions by creating a wastewater effluent instead) and/or from one life cycle stage to another (e.g., from use and reuse of the product to the raw material acquisition phase). If an LCA was not performed, the transfer might not be recognized and properly included in the analysis because it is outside of the typical scope or focus of product selection processes. This ability to track and document shifts in environmental impacts can help decision makers and managers fully characterize the environmental trade-offs associated with product or process alternatives. By performing an LCA, researchers can:

· Develop a systematic evaluation of the environmental consequences associated with a given product.

· Analyse the environmental trade-offs associated with one or more specific products/processes to help gain stakeholder (state, community, etc.) acceptance for a planned action.

· Quantify environmental releases to air, water, and land in relation to each life cycle stage and/or major contributing process.

· Assist in identifying significant shifts in environmental impacts between life cycle stages and environmental media.

· Assess the human and ecological effects of material consumption and environmental releases to the local community, region, and world.

· Compare the health and ecological impacts between two or more rival products/processes or identify the impacts of a specific product or process.

· Identify impacts to one or more specific environmental areas of concern.