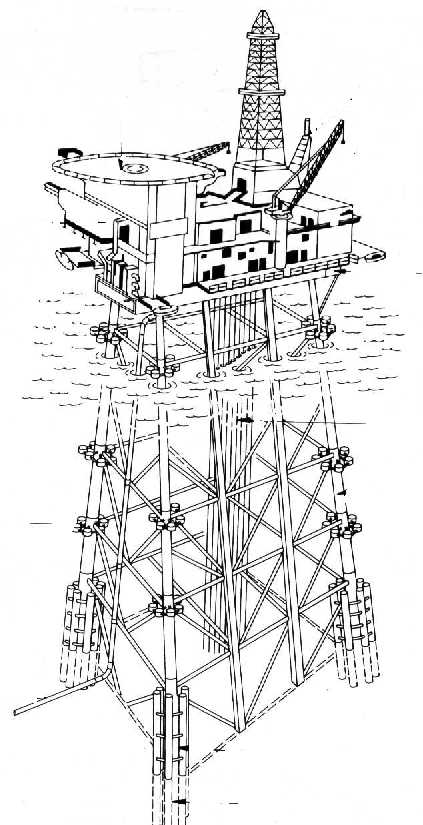

Many parameters influence the design of the jacket, such as required strength,

fatigue, load and life cycle. The pile design results in a balanced combination of

diameter, penetration, pile wall thickness, and spacing.

The design of the pile is very important in the design of the jacket structure itself

and the cost of pile foundation and installation could be as much as 40 % of the total

cost of the platform structure. For example, the typical design requirements for a steel jacket of 150

m would be as described below.

At the seabed the dimensions of the structure are 70 x 65 m and at the top 56 x 30 m

(the top is about 15 m above sea level.

Such a structure weights about 18,500 tonnes and would support topsides

of up to 21,000 tonnes. The jacket can resist forces of up to 50 MN in compression and 10 MN

in tension as well as having large resistance to lateral loads.

Maximum design forces for steel jacket platform are as follow:

- Vertical load: around 50 MN

- Horizontal load: around 5 MN

- Overturning moment: around 10 GN.m

|