Plant sizing involves matching the technical and economical requirements of a given site to establish the CHP unit(s) which is both technically feasible and best fits the site economically. Plant sizing is critical to the economic viability of the scheme, and accurate plant sizing can be facilitated by the use of decision support methods usually on a computer. Through the establishment of a detailed database concerning heat and electrical demand profiles, methodology for plant sizing can be established based on the following considerations :

Operating Regimes for CHP Plants![]() Baseload

Baseload

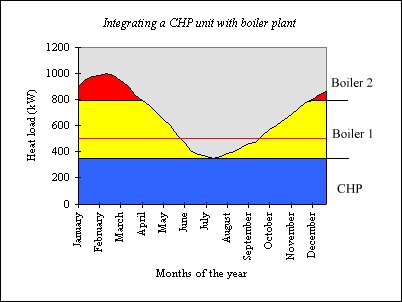

The CHP unit is designed to provide baseload electrical or thermal output, with any shortfall being supplemented by electricity from the grid or hot water/steam from boilers. The graph below shows an example of this with the blue area representing baseload thermal energy. Due to the relative prices of fuel and electricity, electrical baseload sizing though is the more common. The most cost-effective solution, however, may be to size above baseload ( see red dashed line on graph ), even thhough this would obviously involve some heat dumping.

![]() Load Lopping

Load Lopping

CHP units on the market today can have the ability to modulate, which means they are able to

constantly change their output in order to meet a changing demand. When load lopping, the CHP

unit is operated to match plant electricity/heat output with the demand for electricity/heat at

times of Maximum Demand (MD) or High Seasonal Time of Day (STOD) tariffs. During other times,

the baseload is met by conventional means. When modulating on the electricity demand, the

implications of possible heat dumping into the atmosphere via heat exchangers have to be fully

analysed.

![]() Electricity Export

Electricity Export

The CHP unit is operated to provide excess electricity that can be exported to the grid or

other users with the recovered heat being used on site or partly dumped.

![]() Variations

Variations

It may be that in some circumstances, variations such as plant sizing for heat load at

the average heat load during times of peak electricity tariff rate is the most beneficial

option.

Back to Top

|

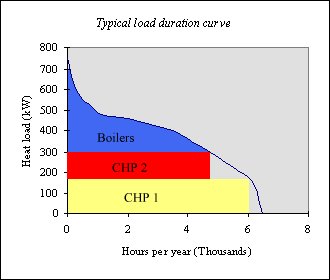

A series of units can operate in cascade to meet the energy demand at the time.

This involves one unit meeting the baseload and smaller units generating as required.

The graph shows how this can be achieved. Single CHP Units are usually the preferred option although some situations dictate the use of two or more small units. The advantages of a single large unit are: |

The main advantage of multiple small units relates to the higher guarantee of emergency supply

cover and electricity maximum demand cost savings during maintenance work.

Back to Top

The CHP plant specification is also dependent upon:

![]() Maximum electrical output required.

Maximum electrical output required.

![]() Thermal heat to electrical power ratio.

Thermal heat to electrical power ratio.

![]() Fuel type used and cost.

Fuel type used and cost.

![]() Grade of heat required.

Grade of heat required.

![]() Utilisation and availability.

Utilisation and availability.

![]() Maintenance requirements, operational and capital costs.

Maintenance requirements, operational and capital costs.

![]() Environmental considerations such as exhaust emissions, vibration and noise.

Environmental considerations such as exhaust emissions, vibration and noise.

Back to Top

Existing decision support methods can save much time in the process of site evaluation and plant sizing. They range from simple rules-based flow charts, to spreadsheets and computer-based decision support packages. There are two factors which differentiate decision support methods :

![]() How accurately the method can

represent the real-life data, such as demand profiles, tariff structures and costs - e.g.

a spreadsheet may have a generic formula to establish the capital cost of a unit, related to

its size ; while a computer-package would have the facility to input the exact price of a

particular unit.

How accurately the method can

represent the real-life data, such as demand profiles, tariff structures and costs - e.g.

a spreadsheet may have a generic formula to establish the capital cost of a unit, related to

its size ; while a computer-package would have the facility to input the exact price of a

particular unit.

![]() Whether or not the method attempts

to apply a criteria to establish a suitable size of unit. i.e. the more simple methods apply

rules to establish a plant size for say baseload, whereas a comprehensive package would have

the capability of performing a cost benefit analysis for any input size of unit.

Whether or not the method attempts

to apply a criteria to establish a suitable size of unit. i.e. the more simple methods apply

rules to establish a plant size for say baseload, whereas a comprehensive package would have

the capability of performing a cost benefit analysis for any input size of unit.

For an initial appraisal into CHP viability for small-scale sites, simple guidelines such as ones laid down by the Energy Efficiency Office’s Best Practice Guides(ref.1) are acceptable. Guideline no. for example offers a simple investment appraisal spreadsheet (self-extracting.exe 35kb) to carry out a preliminary appraisal of the potential of a site for profitable adoption of CHP. The spreadsheet demands simplified real-life data ( e.g. energy demand profiles must be represented as peak or offpeak values ) and uses rules to approximately size the plant to either baseload electricity or peakload electricity. Please understand that this is our version of the spreadsheet suggested by the Energy Efficiency Office and has nothing to do with them.

For plant sizing more specifically, the aid of a computer is essential so factors such as energy profiles, tariff structures, plant capital costs, maintenance costs and interest rates can all be accounted for accurately in a cost benefit analysis exercise to determine the optimum plant size.

Equipment suppliers and consultants usually have in-house computer software not commercially available, but the following packages are some of the packages currently available :

![]() ERGON by Integrated Environmental

Solutions. A comprehensive package offering demand side management, tariff analysis, and

detailed cost benefit analysis for input scenario. Download demo available at http://www.ies4d.com/page4.html

ERGON by Integrated Environmental

Solutions. A comprehensive package offering demand side management, tariff analysis, and

detailed cost benefit analysis for input scenario. Download demo available at http://www.ies4d.com/page4.html

![]() RECIPRO by Thermoflow. As advertised at http://www.thermoflow.com/overview.htm

RECIPRO by Thermoflow. As advertised at http://www.thermoflow.com/overview.htm

![]() EZDOE by Elitesoftware. As advertised at http://www.elitesoft.com/hvacr/elite_ezdoe_info.html

EZDOE by Elitesoftware. As advertised at http://www.elitesoft.com/hvacr/elite_ezdoe_info.html

![]() CEPP by Encotech. As advertised at http://www.encotech.com/frames/CEPP.htm

CEPP by Encotech. As advertised at http://www.encotech.com/frames/CEPP.htm

Also, FREE OF CHARGE,

![]() COGENERATION READY RECKONER by SKM. Not suitable for detailed analysis as energy profiles must take form

of simple peak/non-peak profile. Download available at http://netenergy.dpie.gov.au/info/cogen/readreck.html

COGENERATION READY RECKONER by SKM. Not suitable for detailed analysis as energy profiles must take form

of simple peak/non-peak profile. Download available at http://netenergy.dpie.gov.au/info/cogen/readreck.html

Back to Top

Plant sizing is a key factor in the assessment of the suitability of CHP for the site.

The impact of plant sizing on the financial performance of CHP schemes is further developed

in the project case study,(Project Menu, Conclusions/Results).

Back to Top

1. Best Practise Programme Publications, Energy Efficiency Office, Department of the Environment. http://www.bre.co.uk/default.html